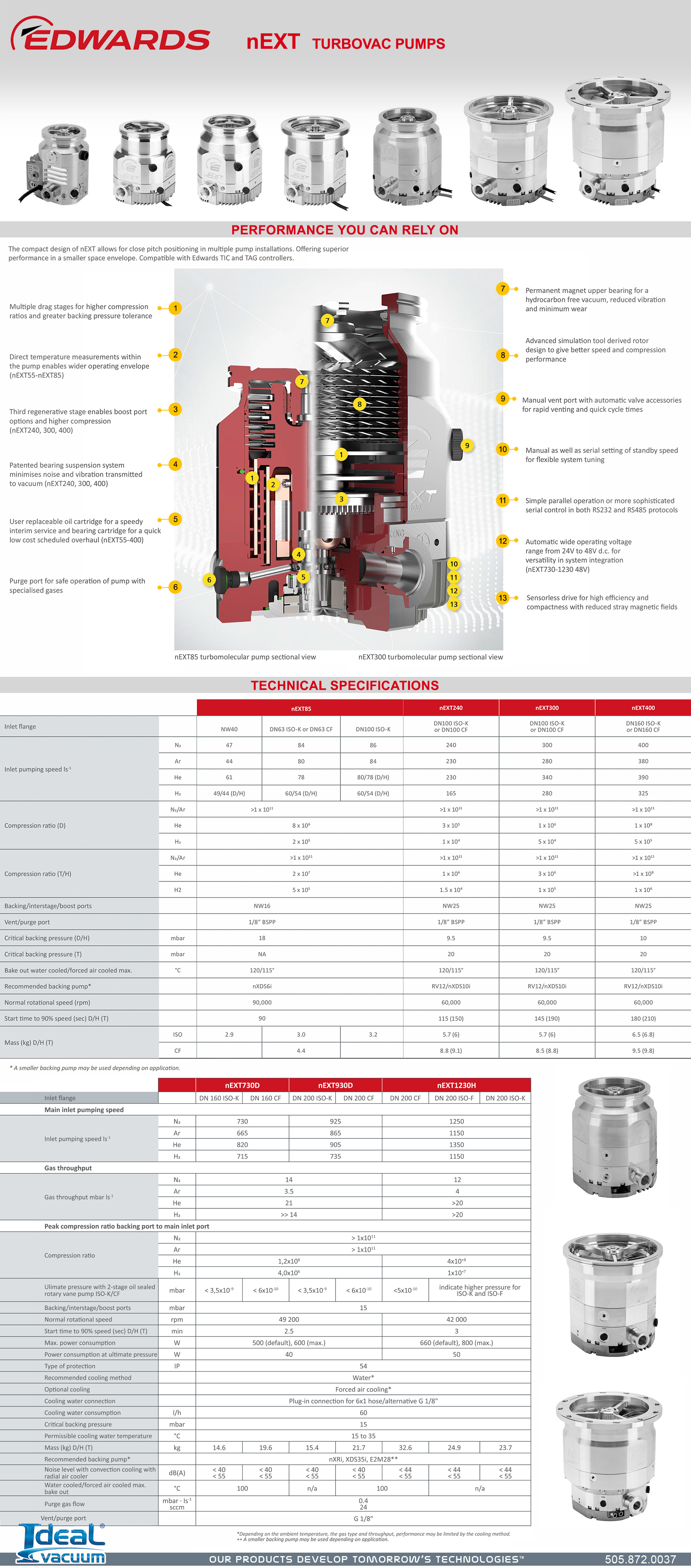

Edwards nEXT730D turbomolecular high vacuum pumps with a DN160 CF, Conflat CF 8.0 inch inlet flange have a pumping speed of 820 liters per second (l/s) and an ultimate pressure of 6 x 10

-10 mbar (4.5 x 10

-10 Torr). This nEXT730D pump has an ISO KF-40 exhaust foreline flange. Optional inlet screens (coarse or fine) are available. The nEXT730D series turbo pumps require 48 VDC input power at a maximum of 600 Watts (normal operation is typically less than 500 Watts). A permanently attached 0.6 meter long 48 volt power cable and a 0.95 meter long control cable are standard to the pump. nEXT730D turbo pumps have a compact onboard controller with RS232, RS485, & USB interfaces, five status LED's, and the possibility to control one accessory (either an air-cooling fan or solenoid vent valve). All that is needed is a suitable power supply and start/stop logic. For laboratory use we recommend the Edwards EPS 800 power supply and either the Edwards TIC or TAG controllers for operating the pump. We also offer a variety of optional accessories, including the TIC and TAG, forced air and water cooling kits, along with solenoid operated vent valves. This nEXT730D turbo pump has Edwards part number B8J200400.

Edwards nEXT730D Turbo Pump Specifications:

- Part Number: B8J200400

- Inlet Flange: DN160 CF, CF 8.0 in.

- Base Pressure: 6 x 10-10 mbar (4.5 x 10-10 Torr))

- Operating Speed: 49,200 RPM

- Operating Position: From horizontal to vertical (inlet up)

- Pumping Speed: 820 l/s

- Cooling: Forced Air or Water

- Exhaust Flange: KF-40

- Operating Voltage: 48 VDC

- Maximum Power: 600 Watts (typical operation < 500 Watts)

- Power and Communication: DB15 serial RS232/RS485 interface, USB

- One accessory port

- Recommended Roughing Pump: nXDS35i or E2M28

The nEXT turbo pumps have a rotor designed to optimize pump performance while maintaining high levels of reliability. The "D" variant of nEXT turbo pumps have both turbomolecular and drag stages for improved tolerance to higher backing line pressures, and have superior pumping speed and compression across all gas species. In addition to enhanced performance, these nEXT730D turbo pumps have field serviceable shaft bearings which dramatically decrease downtime. nEXT D turbo pumps benefit from a compact onboard controller which has drive electronics for controlling pump operation and standby speed, and operating solenoid vent valves (TAV5, TAV6) and air-cooling units (via the 24 VDC accessory port). The integral controller has a 15 DB15 interface for RS232 and RS485 serial communications. A USB port allows the use of Edwards nST2 PC software (free download from link below). The controller also has five indicator LED's which signal the general status, operation, and service status of the pump. The optional TIC turbo instrument controller, or TAG turbo and active gauge controller can control the pump.

Edwards nEXT pumps with a CF flange are true ultra-high vacuum (UHV) pumps with an ultimate pressure into the 10

-10 Torr range (if all-metal intake seal gaskets are used and the vacuum chamber is completely cleaned and baked out). Turbo pumps with ISO flanges are limited (by permeation and outgassing of the rubber/elastomer O-ring seals) to an ultimate pressure in the 10

-8 Torr range. The intake of Conflat flanged nEXT730D pumps can be baked up to 100 °C when the turbo is water cooled. Heater bands for the Conflat pumps are sold separately.

For vacuum system integration applications, the nEXT730D pump can be powered by a suitable user supplied 48 VDC power source. For laboratory applications we recommend the Edwards EPS 800 power supply and either the Edwards TIC turbo instrument controller or the TAG turbo & active gauge controller for controlling the pump. The TIC series of controllers are bench top or rack mountable remote user interface/power sources, which communicate with the Edwards nEXT series pumps through RS232/RS485 and provide full monitoring and control of the turbo pump, and optionally for one or more vacuum gauge instruments. When an Edwards relay box is added, it becomes the control interface between the TIC controller and the mains backing pump, turbo pump flange heater band, and a backing line isolation valve. The TAG turbo and active gauge controller can operate a nEXT730D turbo pump and a vacuum gauge, and its large LED display can show pump speed or vacuum pressure.

The pump instruction manual and Edwards nEXT pump product brochures are available in the downloads section.

Typical Turbo Pump Applications include:

- General clean pumping applications

- Scanning Electron Microscopes - SEM

- Beam lines and high energy physics

- Mass Spectrometry

- Electron Microscopy

- Sample Preparation

- Research and Development

- High Energy Physics

- Industrial

- Semiconductor

- Coatings

- Surface Science Instruments

![]() eDrawings Viewer For Windows

eDrawings Viewer For Windows![]() eDrawings Viewer For MAC.

eDrawings Viewer For MAC.