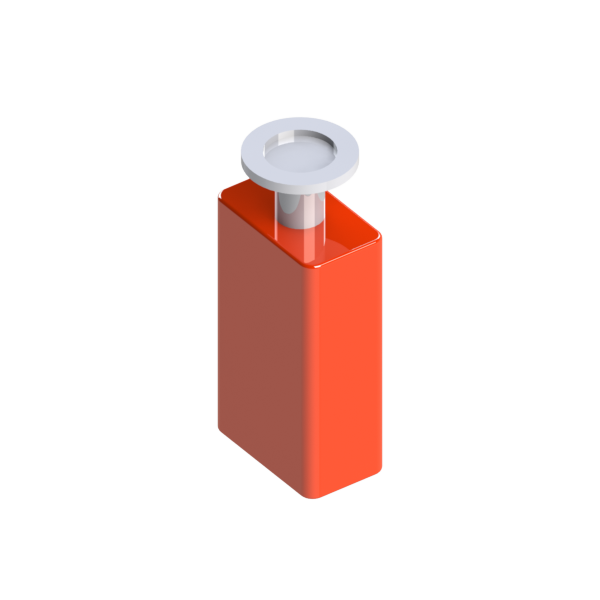

Edwards Active Pirani Vacuum Gauge APG200-MP-NW25 Stainless Steel, KF25, Flange. 10-3 Torr.

Edwards APG200-MP Part Number D1G3021150, (Replaces APG100-MP Part Number D02182000).

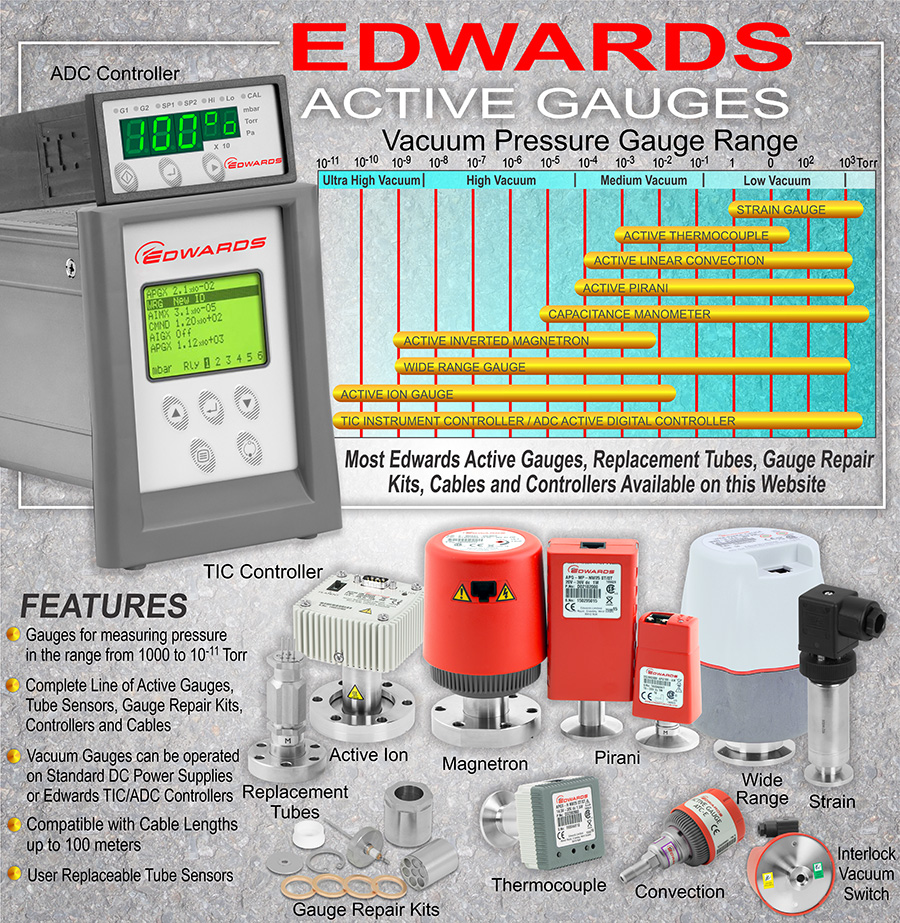

Edwards Active Pirani Vacuum Gauge APG-MP Active Pirani Vacuum Gauge contains a NW25, KF25 vacuum flange, is compact for easy installation, has a linear output. The new Edwards gauges are compatible with all Edwards TIC, ADC, TAG instrument controllers and other active gauge controllers and displays. They are also CSA, C/US approved as well as fully RoHS compliant due to their lead-free construction. They measure pressure from 1000 down to 10

-3 Torr. The signal cables and TIC vacuum gauge controllers are sold separately. The instruction manual for these Edwards APG200-MP series gauges is available in PDF format below. This gague contains a Platinum / rhodium (90/10) filament and can measure pressure down to 10-3 Torr and is stainless steel. These Edwards APG200-MP Active Pirani vacuum gauges has a KF25 NW25 vacuum flange are new with Edwards part number D1G3021150.

If you connected the APG to a Edwards AGC controller or

AGD display, use the set-point adjustment procedure

detailed in the instruction manual supplied with the

unit. If you connected the APG to your own control

equipment, use the procedure on page 22 of the manual.pdf below. The APG200-MP can be mounted in any orientation however the gauge tubes are individually factory calibrated in nitrogen whilst vertical. For correct pressure indication in your chosen gauge orientation, the gauge should be recalibrated at atmospheric pressure. Edwards recommends mounting the gauge tube vertical in order to minimize the build up of process particulates and condensable vapors within the gauge. The APG200 MP is calibrated for use in nitrogen, and will read correctly with dry air, oxygen and carbon monoxide. For any other gas type a conversion is required in order to obtain the correct pressure reading, common gases: nitrogen, argon, carbon dioxide, helium, krypton and neon.

Features Include:

- Easy Access to signal cable with compact enclosure

- Adjustable set point for simple process control and interlocking

- Set Points

- Remote calibration possible

- Pressure range 10-3 Torr

Pirani vacuum gauges can be classified as a thermal conductivity gauge being very similar to the thermocouple gauge where the resistance of the heated wire is measured to determine vacuum pressure. A Pirani gauge is designed to measure the resistance imbalance where the heated filament forms one of the arms of a Wheatstone bridge circuit. As the vacuum pressure increases, gas molecules transport heat away from the filament, and the resistance of the pressure sensor will move to a lower value which unbalances the circuit. The vacuum pressure is therefore calculated from the pressure induced imbalance in the Wheatstone bridge circuit. Just as with the thermocouple gauges, thermal conductivity by molecular collisions increases linearly with pressure over the 0.001 to 1 Torr pressure range. However, the heat removal becomes non-linear as the pressure is further increased into the viscous flow regime, where gas-gas collision can reorient molecules back towards the heated wire. Molecules have to collide many times before they reach the outer body of the sensor (the thermal sink). The convection-enhanced Pirani gauges take advantage of the convention current inside the sensor to extend its pressure measurement range all the way to atmospheric pressure.

The Pirani gauge is an indirect pressure measurement sensors where measured readings are gas-type dependent. Some caution should be advised from the facts that heavier gases have poor heat transfer rates and that the standard convention-enhanced Pirani gauges are calibrated for N2 (basically the same calibration as Air). This could lead to dangerous overpressure conditions when back filling a vacuum systems with a heavier gas like argon. The danger arises if the vacuum system operator does not correct the gauge display reading for the correct gas-type, for example, a standard gauge calibrated for N2, displays 24 Torr when the chamber is at 760 Torr of argon. The operator would be fooled into thinking that the chamber was still under vacuum and continue to increase the system to a critical over-pressured state. Another source of error can be produced if the convection-enhanced Pirani gauge is not mounted correctly, most commercial sensors require that they are mounted parallel to the ground. This keeps the convention current inside the sensor flowing in the designed direction (errors of 20% or more can easily be introduced if the convention-enhanced Pirani sensor is not mount horizontally).

Rapid evacuation of these convection-enhanced Pirani sensors will produce significant measurement error for a short period of several seconds. As the rapidly pumped gases expand, the removal of heat from the pressure sensor filament is not a normal convection current but is instead driven by forced convection. While the vacuum pressure is dropping rapidly the gases expand and cool, this provides a secondary pathway for removing heat from the hot sensor wire. The convection-enhanced Pirani gauge can falsely display high pressures up to 1000 Torr during system evacuation. Once the flow of gases is stopped the pressure reading will again stabilize to a realistic measured value. For these reasons, convection-enhanced Pirani gauges are not well suited for measuring pressure changes under dynamic pumping conditions. Overall, the convection-enhanced Pirani is a popular cost effective rough vacuum pressure gauge which can measures from Atmosphere to 1x10-4 Torr with those measurements below 1 Torr being most accurate.

![]() eDrawings Viewer For Windows

eDrawings Viewer For Windows![]() eDrawings Viewer For MAC.

eDrawings Viewer For MAC.