MBraun Thermal Evaporator - MB Evap S/A, Thin Film Co-Deposition System, Stainless Steel Bell-Jar Chamber - 13 x 17 inch, 4 Thermal Sources and 2 Inficon QCM Thickness monitors with new Pfeiffer HiPace 300 Turbo, Refurbished.

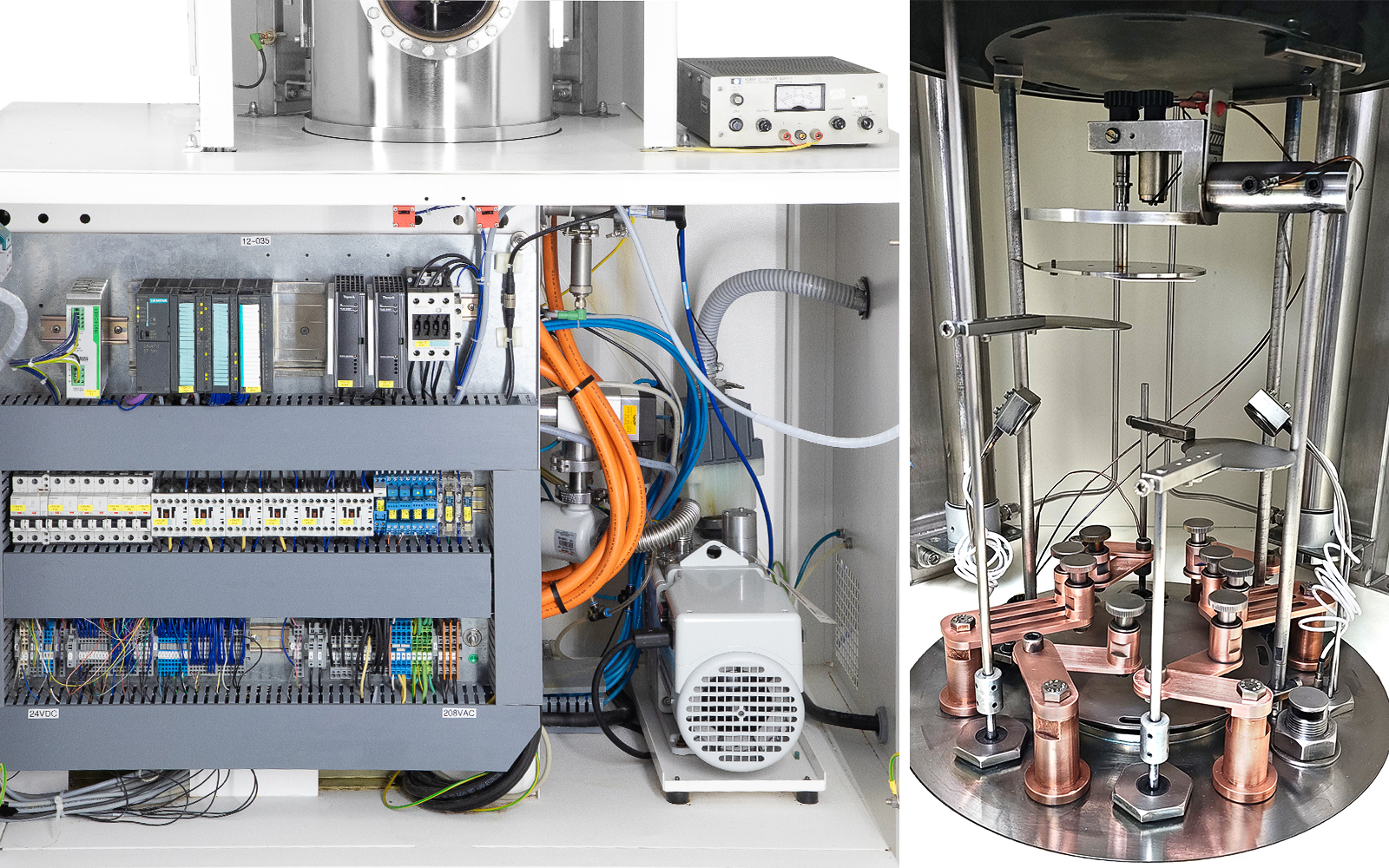

This refurbished Mbraun Evap S/A vacuum coating chamber (2012 manufactured year) is equiped with a brand new HiPace 300 turbo pump and a brand new Edwards 12 rotary roughing pump. The tool is in excellent working condition. The interior of the chamber has been grit blasted to remove all possible contaminants from previous usage. The tool is suitable for thermal evaporation of high melting point metals and dielectrics like gold, titanium, and oxides. It has a stainless steel bell-jar chamber that is 13" diameter x 17" height. The maximum evaporation throw distance is 10" with substrate holder rotation, it can be increased to 12" with no substrate rotation assembly, suitable for lift-off metal deposition. The substrate holder can take a maximum of 4" x 4" sample sizes with rotation during deposition or 6" x 6" samples with no rotation. The chamber has 4 thermal evaporation sources that have a loading capacity of about 1 cc each.

This MBraun Thermal Evaporator it is equipped with many features, including a new custom made 4-inch rotary substrate holder. It has 2 Inficon QCM sensors, and two new quartz crystals installed, an Inficon SQC-310C co-deposition controller with manual and auto process modes. The deposition process can be sequential or co-deposition. Other features include a 6" viewport to observe the coating progress, pneumatic source and substrate shutters, fail safe mechanisms, an optical safety curtain, visual and audio status indicators in form alarms.

This MBraun Evaporator was manufactured in 2012 and has the following features and capabilities:

- Stainless steel bell-jar chamber (13" Diameter x 17" Height)

- Tool dimensions are 48"L x 32"W x 80" H

- 4" Rotary substrate holder (24VDC power supply not included)

- 4 resistive heating pockets

- 10" evaporation throw distance

- Motorized bell-jar chamber hoist

- 2 QCM film thickness sensors and a SQC-310C codeposition controller from Inficon

- Pneumatic source and substrate shutters

- 6" viewport

- Touch screen GUI screen

- Pfeiffer HiPace 300 Turbo Pump

- Optional apparent boat power measurement and display (not included)

- Optional boat temperature thermocouple and readout (multimeter not included)

- Fail safe mechanisms, deposition rate, power, doors, vacuum safety interlocks

- Visual and audio run status indicators

- Electrical supply system - 3 x 208V AC, 60Hz (3Ph/N/PE)

- Total Load - 16A

- 4 boat power sources - 2kW, 30 - 1800°C boat temperature

- Base pressure 5x10-7 Torr , Pfeiffer cold cathode vacuum gauge may need to be replacement

- Max working pressure - user set, 5x10-3 Torr

- Substrate material, shape and size - Si wafers up to 4"

- Substrate rotation speed - user set

- Evaporation boat/rods sizes - 1 - 4" length, 1cc load capacity

- 100 recipes storage, most metal film deposition recipes already installed

- Manual and auto operation mode

- Boat materials -any, W, Moly, Ta, Crucibles

- 1-year limited warranty

MBraun Evap Coating System