Ideal Vacuum XtremeFreez LN2 Liquid Nitrogen Cryogenic Cooling System for ExploraVAC TVAC Thermal Vacuum Chamber Systems.

The Ideal Vacuum XtremeFreez-LN2 (XF-LN2) is a PID-controlled, cryogenic cooling system capable of delivering liquid nitrogen (LN2) to a test item at a temperature of -170°C. LN2 is used because it can provide the fastest cooling rates available for temperatures below -5°C.

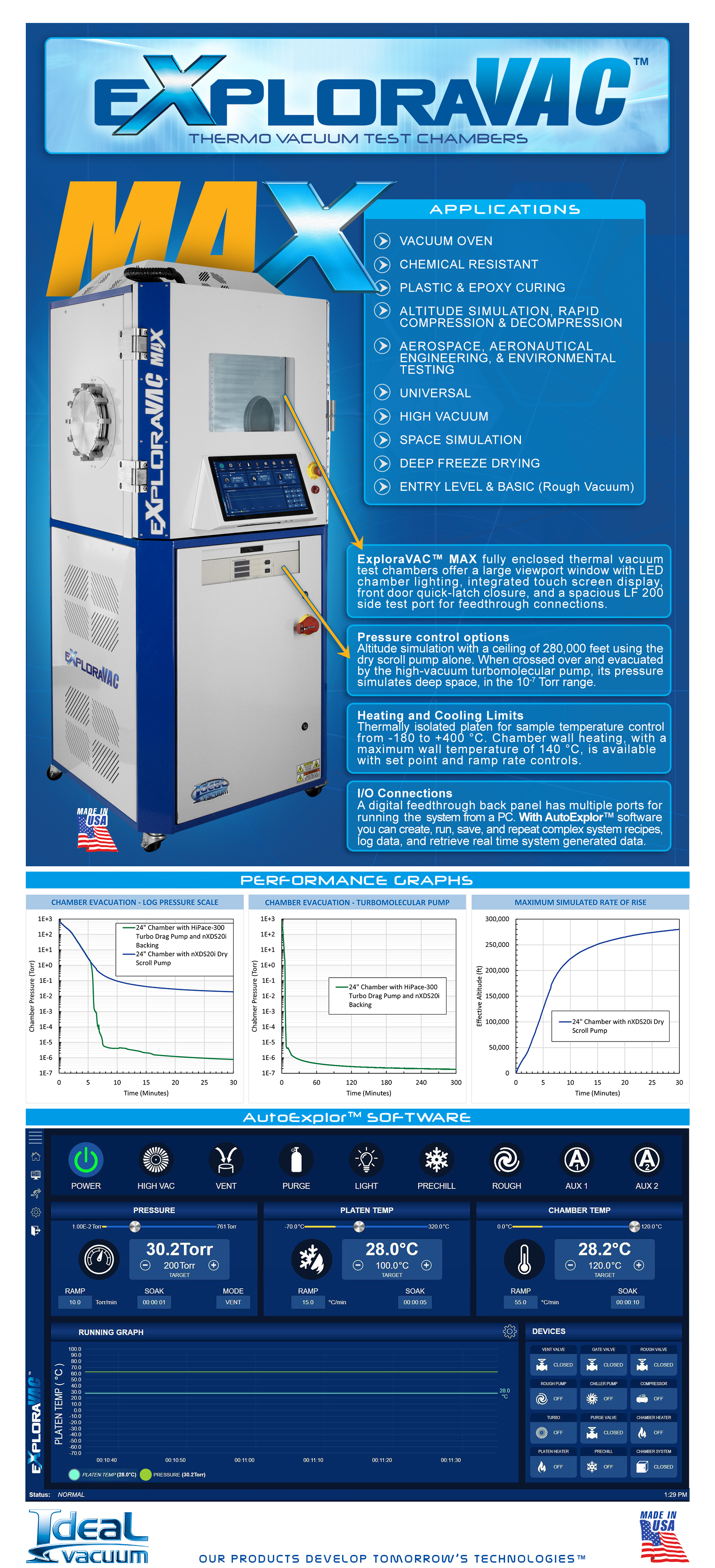

The XF-LN2 system can operate as a stand-alone device, as an RS-232 computer software controlled device using Ideal Vacuum’s AutoExplor software, or as an option for ExploraVAC TVAC thermal vacuum test instruments. For use with an ExploraVAC, the XF-LN2 system is available only in combination with a heated platen. With the XF-LN2 cooling system installed, even hot objects affixed to the ExploraVAC platen can be rapidly cooled to cryogenic temperatures. An ExploraVAC so equipped is often used for space simulation and stress testing aerospace parts. The liquid nitrogen cooling system makes it possible for the platen temperature to change sufficiently fast to simulate an orbiting object moving from light into shadow. Other possible uses for the XF-LN2 system include freeze drying, biological sample freezing, reaction quenching, and cryopreservation.

The XF-LN2 system includes two interchangeable 240 liter LN2 tanks, each with 100 psig pressure relief valves and electronic liquid level sensor gauges, and an assembly consisting of an electronics control module and valve manifold. The assembly is attached to one of the tanks when delivered. The control module houses the PID and other electronics needed for operation, a setpoint controller, and a serial port for connecting to the ExploraVAC instrument, or a computer. The valve manifold has LN2 compatible solenoid operated valves which appropriately route the flow of liquid and/or gaseous nitrogen based on internal logic.

Cryogenic liquid transfer is through two (2) flexible, vacuum insulated, armored hoses. The transfer hoses connect the ExploraVAC TVAC platen cooling tube or user’s test item and the XF-LN2 valve manifold. Additional flexible transfer hoses connect between the two tanks and the tanks to the XF-LN2 valve manifold. All XF-LN2 hoses use standard 3/4”-16, 45° UN/UNF (SAE) flared fittings (CGA-295).

Liquid nitrogen is typically dispensed from the tank with the higher liquid level. XF-LN2 logic opens and closes the proper valves to produce differential vapor pressure between the two tanks. This forces LN2 from the supply (dispensing) tank through the ExploraVAC platen, or user’s test item. Depending on the temperature of the nitrogen exiting the platen or test item, it is either recovered as liquid in the secondary tank, or exhausted out of the system. XF-LN2 logic automatically determines the supply tank, and directs the exiting nitrogen for the most efficient use of the remaining LN2.

User safety is paramount. All safety warnings and procedures must be followed for safe handling and transfer of cryogenic liquid. All XF-LN2 plumbing components are rated for cryogenic use. The system is engineered with 100 psig pressure relief valves on both tanks and on the valve manifold. As an additional safeguard, the manifold includes several 150 psig non-resettable burst discs. The strategic location of pressure relief valves and burst discs in the manifold ensure that every possible closed zone has a pressure relief pathway.

For technical specifications and performance data for the XtremeFreez-LN2 liquid nitrogen cooling system, please download the user manual.

We also offer solutions if you have a large house/facility LN2 supply, or other house coolant, such as industrial cold water. Please contact our engineering department to discuss options for your unique requirements.