At Ideal Vacuum, we custom-build each of our

ExploraVAC™ Unlimited turn-key bakeout systems designed to surpass our customers’ needs. This basic listing is for an

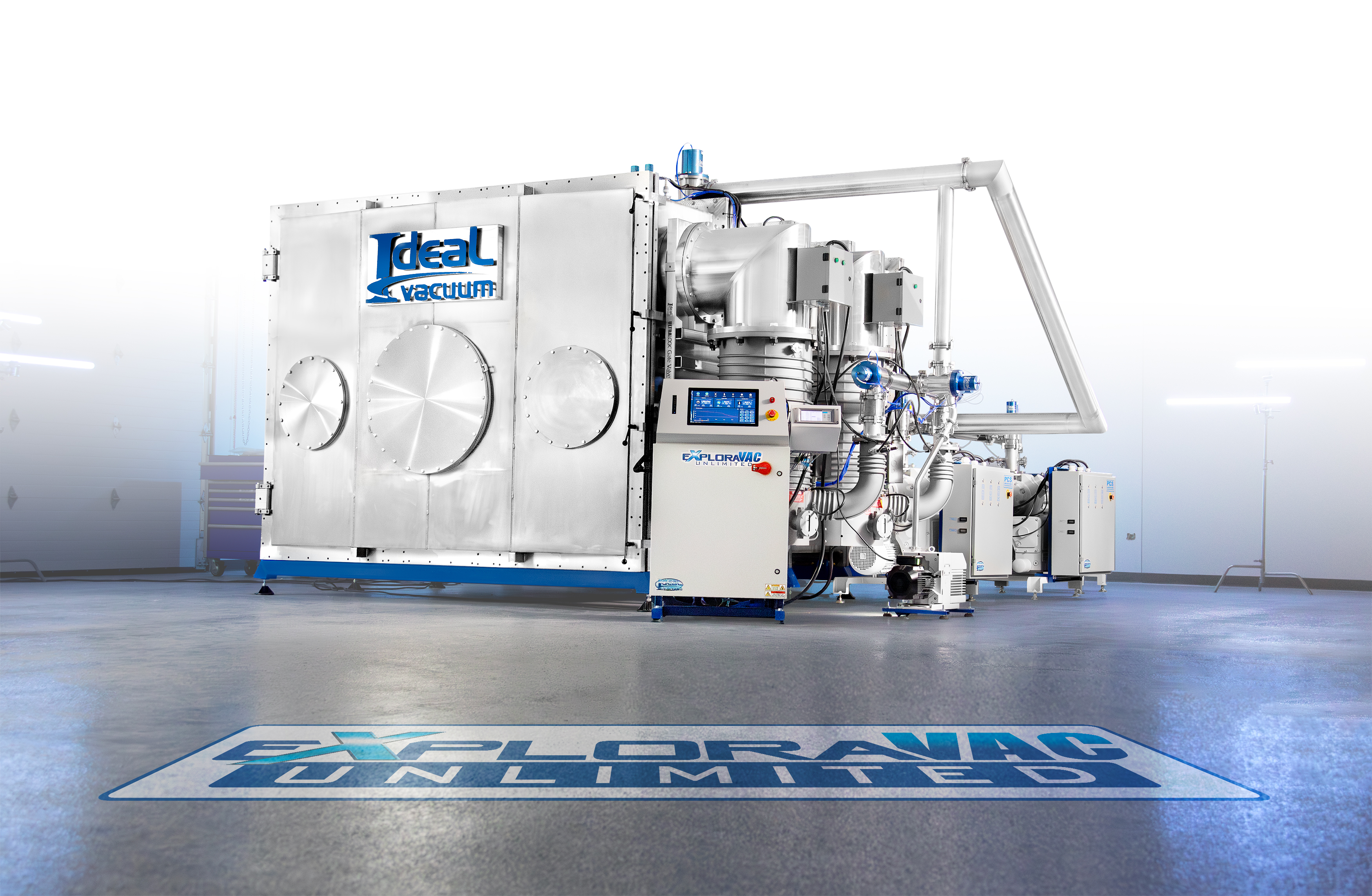

ExploraVAC™ Unlimited system composed of two sectional chambers sections with internal dimensions of 3x3x6 ft, having a 54 cubic feet volume, being constructed of 304L stainless-steel, and based on our expandable sectional chamber design with hinged access doors including multiple large ISO ports for easy mounting of feedthroughs, windows, and instrumentation. It includes IR lamps that quickly transfer even heating directly into the sample piece via radiative heat transfer, driving off contaminants like silicone oils. This system is equipped with 3 each IR bulb chandeliers and custom sample holders, to deliver controlled heating up to 4800 Watts, to bakeout at temperatures as high as 200 °C. An integrated quartz crystal microbalance (QCM) is included in the system to monitor the rate and intensity of outgassing, to gauge when outgassing is complete. An Edwards nXR90i clean-dry rough vacuum pump is used to pull the system down to ultimate pressure of 20 mTorr. Our bakeout systems also include a series of foreline traps that capture the outgassed contaminant compounds during processing, allowing them to be safely collected and properly disposed. This preconfigured ExploraVAC™ Unlimited system is a perfect choice for bakeout applications, such as, solar panels, battery cells, silicone oil recovery, ceramics, or satellite subassembly manufacturing..

Engineered Without Limits – Watch the ExploraVAC Trailer

The

ExploraVAC™ Unlimited degassing system is purpose-built for vacuum bake-out processes where removing volatile residues is essential for mission success. Unlike deep space simulation systems, these chambers operate at rough vacuum levels with integrated infrared (IR) heating and quartz crystal microbalance (QCM) monitoring. This combination ensures rapid heating of components, continuous monitoring of outgassing rates, and reliable determination of when the bake-out process is complete. These systems are commonly used by satellite and solar panel manufacturers who must drive out silicone oils and other volatile byproducts left behind during fabrication. Without proper degassing, these residues would outgas in space, contaminating sensitive spacecraft optics, sensors, and electronics. By using an

ExploraVAC™ Unlimited degassing system, engineers can ensure clean, flight-ready hardware that meets strict aerospace contamination control requirements.Beyond satellite hardware, vacuum bake-out is widely applied across industries where cleanliness and stability in vacuum environments are paramount. Whether preparing optical assemblies, semiconductor wafers, or high-purity materials, these systems deliver the controlled heating, vacuum performance, and process monitoring needed for dependable results.

The system is powered by the

ExploraVAC™ Unlimited Control Platform with

AutoExplor™ software on a side mounted control console, has a conveniently angled front panel full touchscreen interface with manual emergency-off switches, supports controlled ascent and descent in pressure for sensitive components, rapid decompression profiles, altitude flight simulations, and much more. Our

AutoExplor™ software package goes beyond expectations, in fact our customers love how easy it is to use, and they learn to drive the

ExploraVAC™ Unlimited system within minutes. It’s such a strong selling point that customers want to buy our systems just to have

AutoExplor™ . In addition, the side mounted control console has a PLC which manages system functions including pump and valve sequencing for efficient pump down cycles and safety interlocks for preventing equipment damage. Ideal Vacuum has our UL 508A panel shop certification that qualifies us as a industrial control panel manufacturer to design, build, and label panels in compliance with UL safety standards.

Our

ExploraVAC™ Unlimited systems are designed for safety & convenience with standard features including integrated inductive door switch for safety lockouts, external light override switch on control console, LED halo view windows for chamber illumination, and additional welded threaded studs for custom mounting (6 per chamber section).

Common ExploraVAC™ Unlimited bakeout system configuration options:

- IR lamps to deliver high power thermal flux for bakeout and conditioning

- Quartz Crystal Monitors (QCMs) to detect when outgassing during a vacuum bakeout is finished

- Custom fixturing to hold sample parts and assemblies

- Custom chandelier fixturing to hold the IR Lamps

- Residual Gas Analyzer (RGA) for in-situ gas analysis

With the

ExploraVAC™ Unlimited system for bakeout and degassing, you’re not just buying a chamber—you’re deploying a future-proof, fully supported bakeout platform. Our systems deliver the performance and flexibility that keep programs on schedule. It’s truly the best of the best, built to help you achieve mission success. ExploraVAC Unlimited systems are engineered for both mission-critical environmental simulation and high-performance vacuum processes. Whether you're running precision-controlled bakeouts, degassing, or thermal processing routines, these systems deliver the flexibility and performance needed to do it all. Unlike bulky, single-piece chambers, the

ExploraVAC™ Unlimited system features a sectional architecture so large systems ship in manageable sections and assemble quickly at your site, reducing freight cost and installation complexity. Each section is engineered for precise alignment and sealed integrity, with front and rear doors, multiple viewports, and broad compatibility with integrated subsystems—so your layout matches your workflow.

ExploraVAC™ Unlimited bakeout systems are ideal platforms for applications, such as:

- Satellite solar panel degassing to remove silicone oils

- Contamination control for spacecraft components

- Vacuum bake-out of optics, mirrors, and coatings

- Electronics assemblies requiring ultra-clean performance

- Semiconductor wafer processing and degassing

- Preparation of adhesives, resins, and composites

- Degassing of vacuum lubricants and specialty materials

- Outgassing studies for new materials and coatings

About Space Simulation:

The conditions felt in space are extreme. Satellites, CubeSats, and spacecraft experience constant high vacuum and large temperatures swings during the day-night cycle as they pass into the suns unfiltered rays and then into the earth’s cold shadow. For example, an object in low earth orbit without temperature regulation mechanisms may reach -170 °C in the night and 123 °C in the day. Due to the high cost of launching an object into space, it is crucial, and often mandatory, to rigorously test all individual components and the entire assembled device before deployment.

Other Applications Include:

- Battery cell bakeout

- Solar panel degas and bakeout

- Silicone solar panel bakeout

- Ceramic bakeout

- Solar cell testing

- Vacuum chamber for optics bakeout

- Electronics vacuum bakeout system

- Semiconductor vacuum degassing chamber

- Vacuum chamber for outgassing studies

- Quartz Crystal Microbalance (QCM) bake out monitoring

- Infrared (IR) heated vacuum chamber