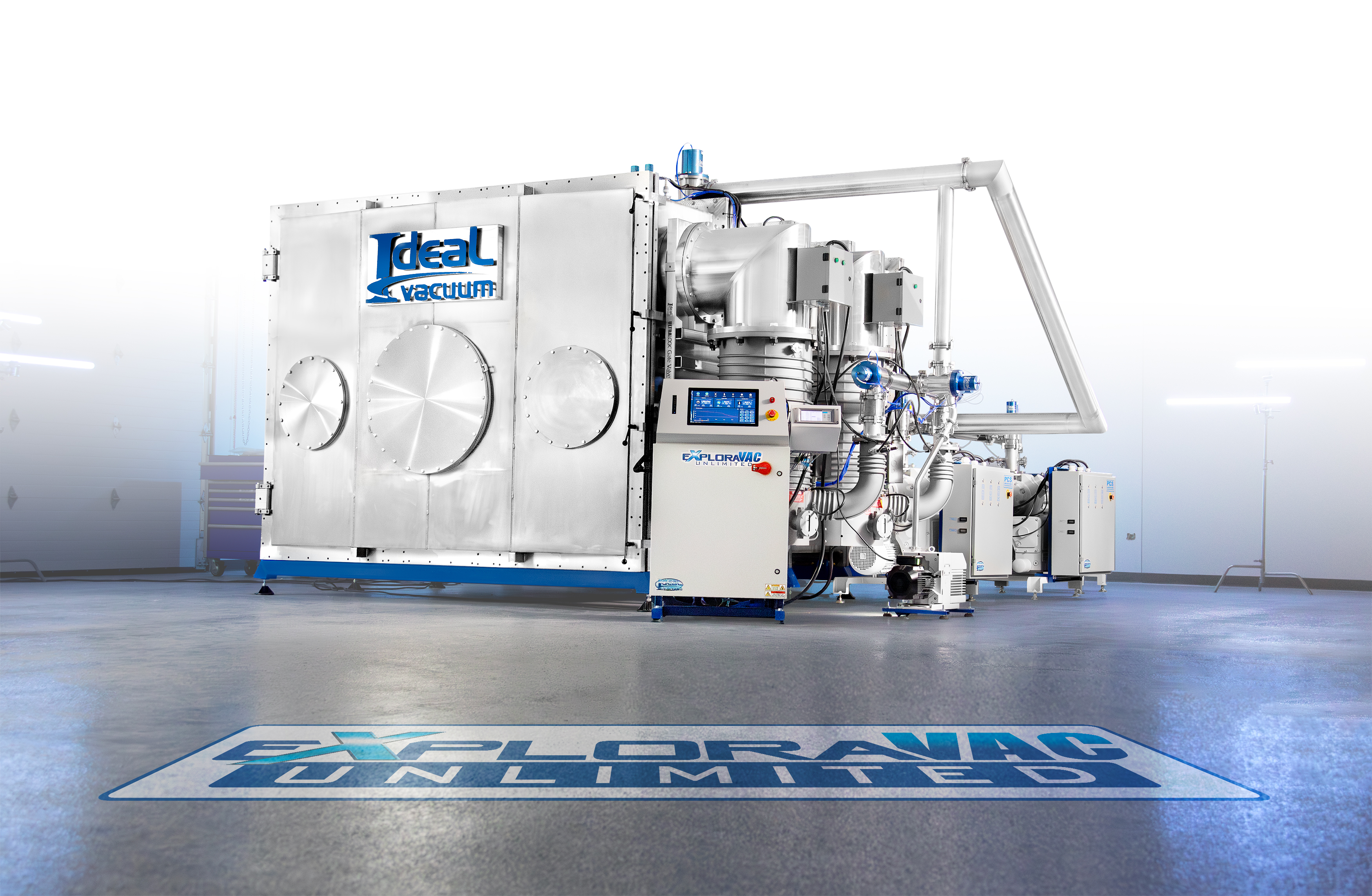

At Ideal Vacuum, we custom-build each of our

ExploraVAC™ Unlimited turn-key altitude simulation systems, are designed to provide rapid decompression and precise pressure control conditions, to surpass our customers’ needs. This basic listing is for an

ExploraVAC™ Unlimited system composed of a single sectional chamber with internal dimensions of 3x3x3 ft, having a 27 cubic feet volume, being constructed of 304L stainless-steel, and based on our expandable sectional chamber design with hinged access doors including multiple large ISO ports for easy mounting of feedthroughs, windows, and instrumentation. These altitude simulation systems are designed to operate above ambient atmosphere to 1100 Torr (21 psi absolute). The selected pumping system includes Leybold SV630BF rotary vane pump with WAU-2001 roots blower, with massive 1,200 CFM of pumping speed, which pulls the system down, to ultimate pressure of 10 mTorr in less than 15 seconds. These pumps provide sufficient pump down speed to meet the customer's MIL-STD 810G, DO-160, and ANSI/VITA47-2005 test requirements. All necessary equipment, such as valves, gauges, sensors, and necessary plumbing are included. Customer supplied recirculating or fresh water (3.1 gpm minimum) to cool the SV630BF pump, and compressed air (70 psi minimum) to operate the pneumatic valves, is required. This system requires one 440-480 VAC, 60 Hz, 3Ø, 85A electrical power feed.

Engineered Without Limits – Watch the ExploraVAC Trailer

Altitude simulation systems are essential tools for aerospace, defense, and high-performance manufacturing industries that need to replicate high-altitude or rapid decompression conditions here on Earth. By precisely controlling chamber pressure, these systems allow engineers to verify how components, assemblies, and complete products will perform in reduced-pressure environments. ExploraVAC™ Unlimited altitude simulation chambers are used by satellite builders, aircraft manufacturers, defense contractors, and research laboratories to ensure compliance with demanding test standards and to validate safety, reliability, and mission-readiness of critical hardware.

The system is powered by the

ExploraVAC™ Unlimited Control Platform with

AutoExplor™ software on a side mounted control console, has a conveniently angled front panel full touchscreen interface with manual emergency-off switches, supports controlled ascent and descent in pressure for sensitive components, rapid decompression profiles, altitude flight simulations, and much more. Our

AutoExplor™ software package goes beyond expectations, in fact our customers love how easy it is to use, and they learn to drive the

ExploraVAC™ Unlimited system within minutes. It’s such a strong selling point that customers want to buy our systems just to have

AutoExplor™ . In addition, the side mounted control console has a PLC which manages system functions including pump and valve sequencing for efficient pump down cycles and safety interlocks for preventing equipment damage. Ideal Vacuum has our UL 508A panel shop certification that qualifies us as a industrial control panel manufacturer to design, build, and label panels in compliance with UL safety standards.

Our

ExploraVAC™ Unlimited systems are designed for safety & convenience with standard features including integrated inductive door switch for safety lockouts, external light override switch on control console, LED halo view windows for chamber illumination, and additional welded threaded studs for custom mounting (6 per chamber section).

With the

ExploraVAC™ Unlimited system for Space Simulation, you’re not just buying a chamber—you’re deploying a future-proof, fully supported space simulation platform. From research labs to flight-hardware qualification, this system delivers the performance and flexibility that keep programs on schedule. It’s truly the best of the best, built to help you achieve mission success. ExploraVAC Unlimited systems are engineered for both mission-critical environmental simulation and high-performance vacuum processes. Whether you're qualifying flight hardware through altitude and thermal cycling, or running precision-controlled bakeouts, degassing, or thermal processing routines, these systems deliver the flexibility and performance needed to do it all. Unlike bulky, single-piece chambers, the

ExploraVAC™ Unlimited system features a sectional architecture so large systems ship in manageable sections and assemble quickly at your site, reducing freight cost and installation complexity. Each section is engineered for precise alignment and sealed integrity, with front and rear doors, multiple viewports, and broad compatibility with integrated subsystems—so your layout matches your workflow.

ExploraVAC™ Unlimited systems are ideal platforms for altitude simulation applications, such as:

- Aircraft component testing under rapid decompression conditions

- Avionics and electronics qualification to MIL-STD-810 and DO-160 standards

- Battery and power system altitude safety testing

- Satellite and spacecraft subsystem altitude verification

- Defense equipment qualification (radios, sensors, guidance systems)

- Medical device altitude exposure studies (pumps, valves, portable electronics)

- Material outgassing and sealing verification at reduced pressures

- Environmental stress testing for high-performance industrial products

About Space Simulation:

The conditions felt in space are extreme. Satellites, CubeSats, and spacecraft experience constant high vacuum and large temperatures swings during the day-night cycle as they pass into the suns unfiltered rays and then into the earth’s cold shadow. For example, an object in low earth orbit without temperature regulation mechanisms may reach -170 °C in the night and 123 °C in the day. Due to the high cost of launching an object into space, it is crucial, and often mandatory, to rigorously test all individual components and the entire assembled device before deployment.

Other Applications Include:

- Altitude Simulation Chamber

- Altitude Test Vacuum Chamber

- Rapid Decompression Test Chamber

- Reduced Pressure Simulation System

- MIL-STD-810 Altitude Test Chamber

- DO-160 Altitude Qualification Chamber

- Aerospace Altitude Simulation Chamber

- Vacuum Chamber for Avionics Testing

- Environmental Altitude Test System

- ExploraVAC™ Unlimited Altitude Simulation