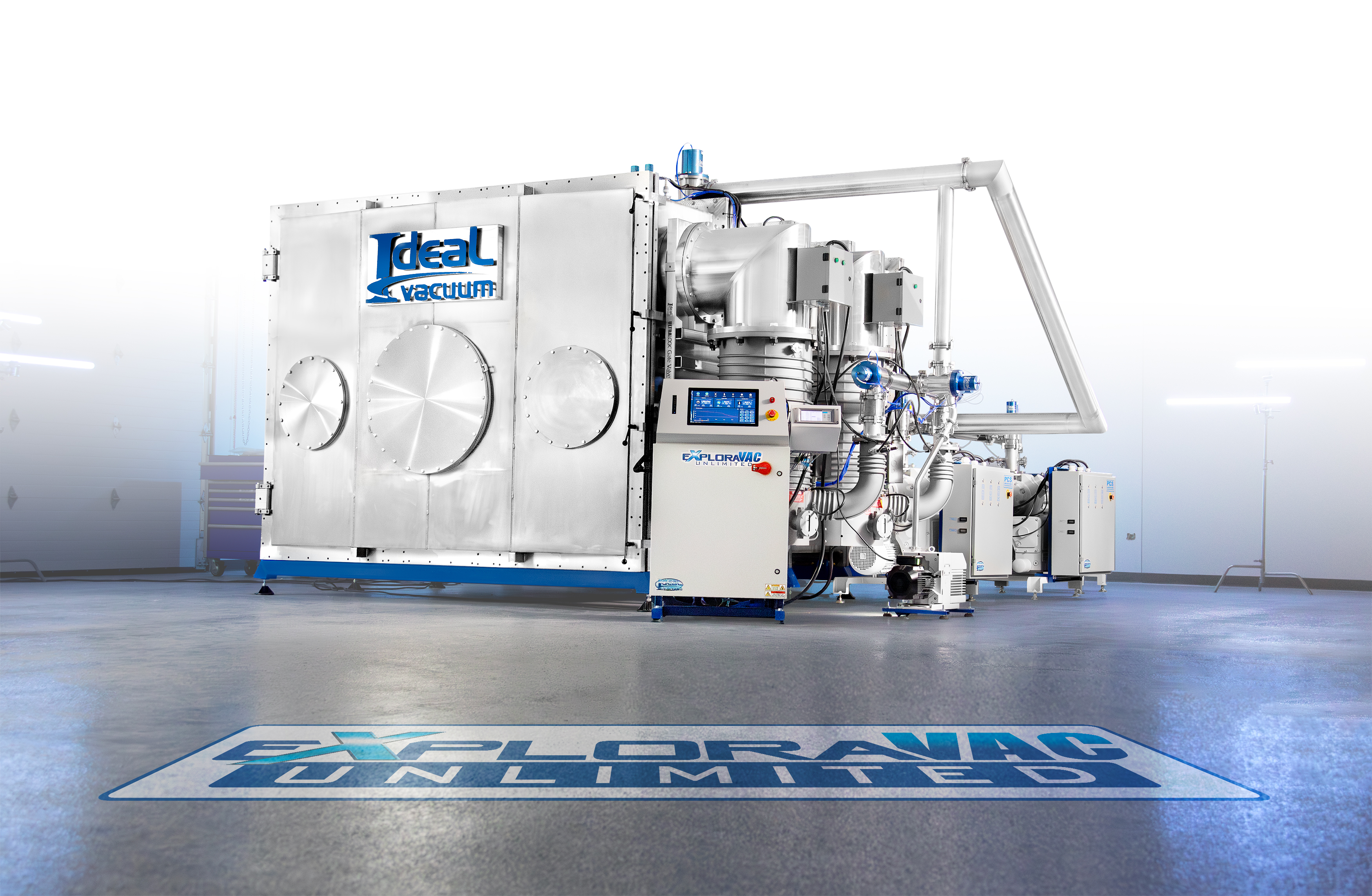

At Ideal Vacuum, we custom-build each of our

ExploraVAC™ Unlimited turn-key thermal high vacuum test chambers, they are designed to surpass our customers’ needs. This basic listing is for an

ExploraVAC™ Unlimited system composed of a single sectional chamber with internal dimensions of 3x3x3 ft, having a 27 cubic feet volume, being constructed of 304L stainless-steel, and based on our expandable sectional chamber design with hinged access doors including multiple large ISO ports for easy mounting of feedthroughs, windows, and instrumentation. It includes full-pullout platen which is liquid nitrogen cooled (LN2) down to -170 °C, resistive heating up to 375 °C, and having a thermal ramp rate ranging from 7 - 10 °C/min for fast cycling. The selected high-vacuum pumping system includes clean-dry vacuum pumps, Edwards nXR60i roughing pump and Edwards nEXT1230 turbo high-vacuum pump, which pull the system down to ultimate pressure of 5x10-7 Torr in less than 2 hours. This preconfigured

ExploraVAC™ Unlimited system is a perfect choice for space simulation testing of satellite batteries, solar panels, instrumentation, or complete small satellite assemblies.

Engineered Without Limits – Watch the ExploraVAC Trailer

Our

ExploraVAC™ Unlimited systems are designed for safety & convenience with standard features including integrated inductive door switch for safety lockouts, external light override switch on control console, LED halo view windows for chamber illumination, and additional welded threaded studs for custom mounting (6 per chamber section).

The system is powered by the

ExploraVAC™ Unlimited Control Platform with

AutoExplor™ software on a side mounted control console, has a conveniently angled front panel full touchscreen interface with manual emergency-off switches, supports controlled ascent and descent in pressure for sensitive components, rapid decompression profiles, altitude flight simulations, and much more. Our

AutoExplor™ software package goes beyond expectations, in fact our customers love how easy it is to use, and they learn to drive the

ExploraVAC™ Unlimited system within minutes. It’s such a strong selling point that customers want to buy our systems just to have

AutoExplor™ . In addition, the side mounted control console has a PLC which manages system functions including pump and valve sequencing for efficient pump down cycles and safety interlocks for preventing equipment damage. Ideal Vacuum has our UL 508A panel shop certification that qualifies us as a industrial control panel manufacturer to design, build, and label panels in compliance with UL safety standards.

Space Simulation Optional Added Features: For simulating deep-space thermal environments for satellite & advanced propulsion research testing

- Cryogenically cooled shroud for surrounding the test article with ultra-cold surfaces that radiatively absorb heat

- High emissivity coatings, e.g., Aeroglaze Z306 coated shrouds (flat black)

- Mylar-insulated cryopumping panels to improve vacuum levels

- Multi-layer insulation (MLI) panel materials

- Solar simulators / artificial sun options for thermal cycling or balancing

- IR lamps to deliver high power thermal flux for bake-out and conditioning

- Thermal Conditioning Units (TCUs) with wide temperature range and uniformity

- LN2 cooled scavenger plate (often termed ConTam plate) for trapping outgassing contaminants

- Quartz Crystal Monitors (QCMs) to detect when outgassing during a vacuum bake-out is finished

- Residual Gas Analyzer (RGA) for in-situ gas analysis in vacuum systems

With the

ExploraVAC™ Unlimited system for Space Simulation, you’re not just buying a chamber—you’re deploying a future-proof, fully supported space simulation platform. From research labs to flight-hardware qualification, this system delivers the performance and flexibility that keep programs on schedule. It’s truly the best of the best, built to help you achieve mission success. ExploraVAC Unlimited systems are engineered for both mission-critical environmental simulation and high-performance vacuum processes. Whether you're qualifying flight hardware through altitude and thermal cycling, or running precision-controlled bakeouts, degassing, or thermal processing routines, these systems deliver the flexibility and performance needed to do it all. Unlike bulky, single-piece chambers, the

ExploraVAC™ Unlimited system features a sectional architecture so large systems ship in manageable sections and assemble quickly at your site, reducing freight cost and installation complexity. Each section is engineered for precise alignment and sealed integrity, with front and rear doors, multiple viewports, and broad compatibility with integrated subsystems—so your layout matches your workflow.

ExploraVAC™ Unlimited systems are ideal platforms for space simulation applications, such as:

- High vacuum capability for upper-stage and in-space engine qualification

- LN2 thermal systems to replicate deep space thermal soak

- Large modular chamber design for accommodating engine test stands

- Instrumentation ports for plume diagnostics (RGA, spectroscopy, thermal cameras)

- Contamination control features for green propellant and advanced cycle evaluation

- Advanced Propulsion Research for qualifying next-generation rocket engines and in-space propulsion technologies

- Methane/LOX Engines (Methalox) to validate ignition, restart, and expansion ratio performance in high-vacuum conditions for upper-stage engines.

- Rotating Detonation Engines (RDEs) study of detonation stability, combustion dynamics, and nozzle efficiency under simulated altitude conditions.

- Electric Propulsion Hall effect, ion, MPD, and VASIMR thrusters in vacuum testing plume diagnostics, erosion studies, and spacecraft interaction testing.

About Space Simulation:

The conditions felt in space are extreme. Satellites, CubeSats, and spacecraft experience constant high vacuum and large temperatures swings during the day-night cycle as they pass into the suns unfiltered rays and then into the earth’s cold shadow. For example, an object in low earth orbit without temperature regulation mechanisms may reach -170 °C in the night and 123 °C in the day. Due to the high cost of launching an object into space, it is crucial, and often mandatory, to rigorously test all individual components and the entire assembled device before deployment.

Other Applications Include:

- Space simulation & Aerospace component vacuum testing

- Satellite testing & degassing

- Space hardware & payload qualification

- Spacecraft materials vacuum testing

- CubeSat space simulation chamber

- Solar panel testing and qualification

- Solar simulator & thermal balance testing

- Battery cell testing for unpressurized cabin air travel

- Advanced propulsion research

- Rocket component space simulation testing

- Thermal vacuum chamber (TVAC) for space hardware testing