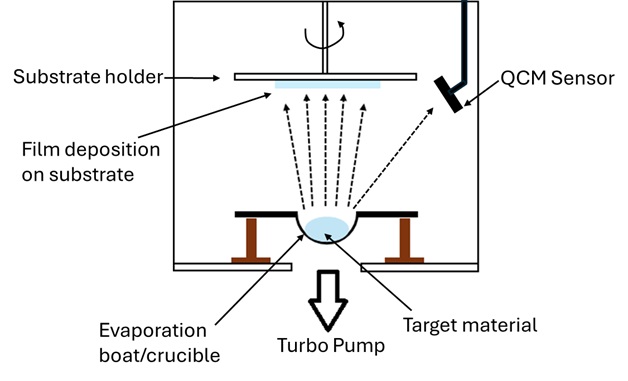

This box vacuum coater system is designed for the forensic vapor metal deposition (VMD) process, specifically latent fingerprint development in a lab environment. The chamber is 20 x 20 x 20 inches cubed in volume and is made of stainless steel. It has 4 thermal evaporation sources: for either evaporation boats, rods or crucibles. It is equipped with many features, including a 6-inch rotary substrate holder for flat substrates like fabrics, glass, and paper. This is interchangeable with a horizontal chucked spindle for irregular samples like bullet casings, water glasses, knives, doorknobs, and weapons. It has 2 substrate plate radiant heaters, 2 Inficon QCM sensors, in-built thickness controller with manual and auto process modes. The deposition process can be sequential or 2 pocket co-deposition. Other features are 2 reactive deposition gas inlet ports, door viewport with gravity shutter and chamber lighting to observe prints development, pneumatic source and substrate shutters, water cooled electrode feedthroughs, fail safe mechanisms, visual and audio status indicators in form of stack lights and alarms.

The system includes a built-in 15.5” touch screen display equipped with non-expiring basic version of

AutoExplor™ software, run by an onboard Windows computer which can control all chamber and deposition process functions. All electronic components are UL certified for North America. The system has 2 boat source power supply (4kW, 400A), 2 variacs – 45A. The system installed with direct apparent boat power, voltage and load current measurement modules and display unit in the lower cabinet.

The system can vaporize common metals for VMD: gold, copper, nickel, zinc, chromium, aluminum. The chamber is rough pumped by an Edwards nXDS20i dry scroll pump and fine pumped by Pfeiffer HiPace 300 turbo molecular pump to a base pressure of 3 x 10-7 Torr when properly conditioned.

We can customize recipes for your VMD processes. We thoroughly test run your processes before shipping. In-person or virtual training of the SOP is also provided upon request. Our system comes with a standard one-year warranty. The lead time is 90 days after the purchase order is confirmed.

ExploraVAC PVD Box Coater, 20 Inch:

- Fully Enclosed 20” Welded SS Vacuum Chamber with Interior Shields

- 4 sources, 1.0 cc, 2 - 4’’ Boats- Tungsten, Molybdenum, Tantalum, Rods, Crucibles

- VMD Metals : Au, Zn, Cu, Ni, Ti, Cr, Al, Sn, Ag, In

- Rotary Substrate Holder/Spindle

- Pneumatic Shutters

- 2 QCM Sensors

- Substrate Radiant Heaters

- Door with 6’’ Viewport with gravity shutter

- Quick-Latch Front Door Closure

- Through Viewport LED Chamber Lighting

- 15.5” LCD Touch Screen Display

- Edwards nXDS20i Dry Scroll Vacuum Pump

- Pfeiffer HiPace 300 Turbo Pump

- Apparent Boat Power Measurement and Display

- Evaporator Source Power - 4kVA, 400A

- Visual and Audio Run Status Indicators

- Fail Safe Mechanisms

Thermal PVD Overview

Figure 1. Schematic diagram of thermal evaporation of target material in a boat during a PVD process.

Thermal evaporation Physical Vapor Deposition (PVD) is a simple method used to deposit thin films of material onto substrates in a vacuum environment. Both metallic and non-metallic films can be deposited by this method. During the deposition process, a material is thermally heated until it melts and vaporizes, and then the vapor lifts off and condenses onto a cooler substrate, forming a thin film. Some materials like Cr simply sublimes without melting, achieving the optimum deposition vapor pressure. The mean free path of the vapor molecules must be long enough to avoid collisions with residual gases in the chamber. This is achieved by ensuring the base pressure falls below a calculated threshold before initiating evaporation.

Our chambers are fine pumped by Pfeiffer HiPace turbo molecular pumps to below 10-7 Torr within a few minutes, at this gas pressure, the mean free path of the vapor is increased to beyond 40 inches which is about four times greater than the deposition process throw distance. This ensures efficient and contamination-free deposition of our systems. A QCM sensor is a common film thickness monitor incorporated into PVD chambers to constantly give feedback on rate of deposition and film thickness.

Application: Forensics, Fingerprint Mark Imaging using Vacuum Metal Deposition (VMD)

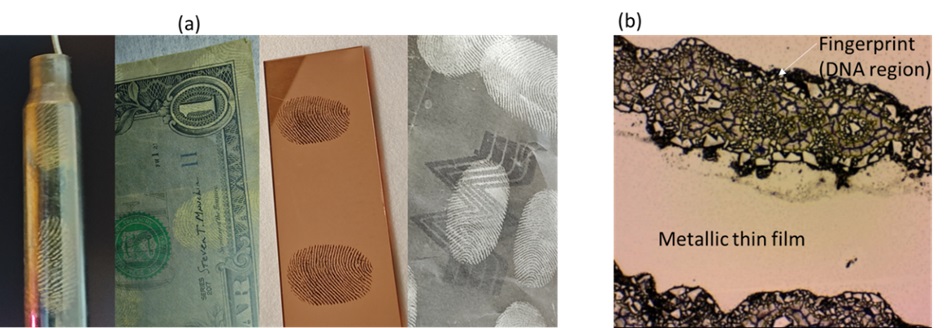

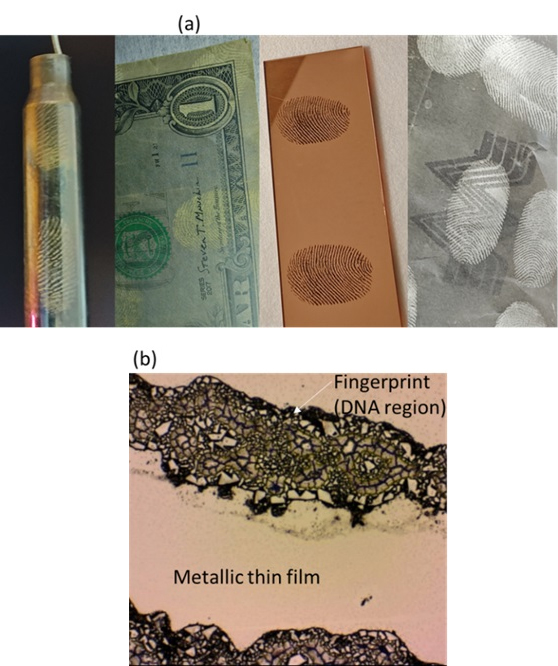

Fingerprint imaging is a powerful tool utilized by law enforcement and other associated government agencies and private organizations in their forensic criminal investigations. In vacuum metal deposition (VMD), a pair of metallic thin films are used to coat and develop latent fingerprints that may be present on materials recovered from a crime scene. Fingerprint residues are primarily composed of organic compounds such as sweat, oils, and other bodily secretions. These substances create a layer that is physically and chemically different from substrates such as paper, glass, fabrics, wood and metallic surfaces. In VMD, normally the first film to be deposited is gold, followed by zinc. Chromium, silver, tin, copper, aluminum, have also been used to develop latent fingerprints.

Figure 2. (a) Latent fingerprints developed by VMD on a bullet casing, dollar bill, window glass and a fast-food outlet paper receipt. (b) Microscope image of developed fingerprints showing regions where DNA can be extracted for further forensic analysis.

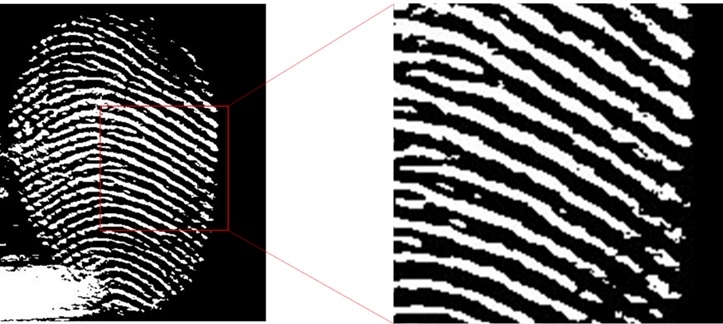

Zinc, being a metal, does not bond effectively with the fingerprint residue organic materials. Hence, in VMD technique for latent fingerprint development, a gold film is often deposited first mainly to enhance adhesion and for contrast improvement where gold creates a high-contrast background against the fingerprint residues. Excitation of the coated films at 300 – 400nm range gives best visual results of the print marks. When a second metal layer (typically zinc) is deposited, it highlights the ridges of the fingerprint by adhering more strongly to the areas without residues, creating a clear and distinct pattern that can be taken for forensic analysis. Gold is also chemically inert and does not react with fingerprint residues or the subsequent metal layers. This helps preserve the integrity of the latent fingerprint, ensuring accurate and reliable development and DNA recovery (Figure 2(b).

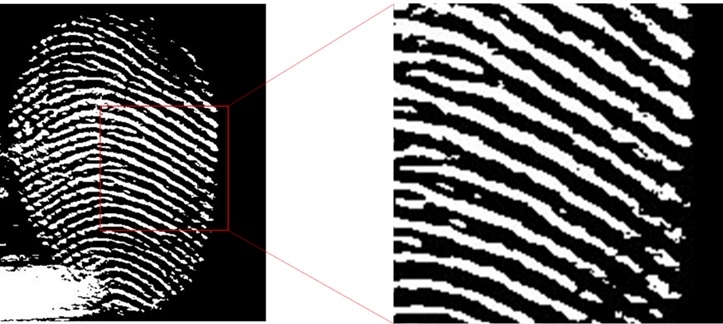

Figure 3. Fingerprints on window glass developed by VMD using a copper and chromium film stack on ExploraVAC PVD Box Coater. The image was processed by image processing software to improve contrast.

VMD has been proven to be the only method so far that is capable of developing prints on fabrics and large pieces of evidence like bedding or exhibits that have aged for several months like a weapon thrown under water. This makes this tool useful in trying to solve cold criminal cases with newly discovered pieces of physical exhibits.