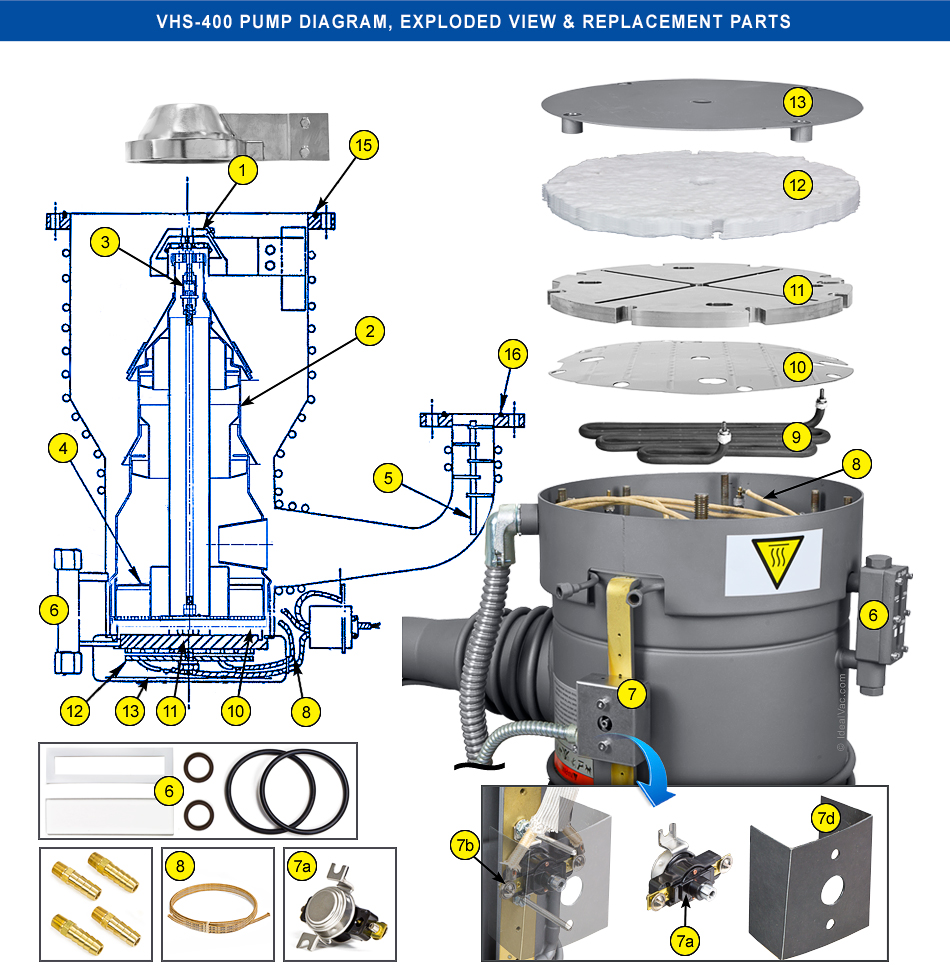

Agilent Varian VHS-400 Water Cooled Vacuum Diffusion Pump, ISO400K Inlet Flange, 17.72 inch OD, Maximum Pumping Speed 8000 l/s Air

Standard Cold Cap, (2) 208 VAC 2200 Watt Heaters, Agilent Varian Part Number L9767307.

The Agilent Varian VHS-400 has been designed to fill a special need in applications where high pumping speeds are required and space limitations demand a compact pump. The VHS-400 pump is a rugged, general-purpose unit with an operating range of 1.4 x 10-3 to <5 x 10-9 Torr at 4400W. The Agilent Varian VHS-400 is ideal for applications requiring fast cycling because of its high pumping speed (maximum rated at 8000 l/s with standard cold cap) air combined with high forepressure tolerance (0.65 Torr with no-load and 0.55 Torr when at full gas load). Backstreaming rate of the unit is 1x10-3 mg/cm

2/ min, without the use of any cooled cold cap.

This Agilent Varian VHS-400 Diffusion Pump Includes:

- ISO 400K (17.72 in. OD) No bolt holes

- ISO 63K (3.75 in. OD) No bolt holes

- Standard Cold Cap

- Recommended Roughing Backing Pump: 30 CFM

- 8000 l/s Maximum Pumping Speed Air

- 208 VAC 3 ph (4400W) with (2) 2200 Watt Heaters

- Water Connections 1/8 in. FPT Tee

- Designed To Be Used With Santovac 5 or IVP 704 Diffusion Pump Oil, 1000cc (1.056 Qt.) full charge

Diffusion pumps use a high-speed jet of vapor to direct gas molecules in the pump throat down into the bottom of the pump and out the outlet. The oil diffusion pump is operated with an oil that has low vapor pressure. Its purpose is to achieve higher vacuum (lower pressure) than possible by use of positive displacement pumps alone. The Agilent Varian VHS-400 can pump down to pressures of <5x10-9 Torr. Diffusion pumps cannot discharge directly into the atmosphere, so a mechanical forepump, roughing pump is typically used to maintain an outlet pressure around 1 mTorr.

These Agilent Varian Diffusion Pumps are very reliable, simple in design and operate with no noise or vibration. Diffusion pumps are still the

most economical means for creating high-vacuum pressures. Diffusion pumps also tolerate operating conditions such as excess particles and reactive gases that

would destroy other types of high-vacuum pumps. They can be ordered with a 3-phase 208, 240, 380, 480 VAC heater harness and with standard or extended cold cap. We stock and sell Santovac 5 diffusion pump fluids for this pump. Please see below in our “Related” section for additional accessories that may benefit your vacuum applications and maintenance needs. We offer a large variety of vacuum greases, oils, vacuum fittings, hoses, vacuum gauges, sensors/transducers, parts and accessories sold separately on this website.

These Agilent Varian VHS-400 diffusion pumps have ISO 400K no bolt inlet flange, operate on 3-phase 208 VAC, standard cold cap and has Agilent Varian part number L9767307. The Agilent Varian VHS-400 diffusion pump user's instruction manuals can be downloaded in PDF format below. These are typical stock items that often ship same day as order is placed.

![]() eDrawings Viewer For Windows

eDrawings Viewer For Windows![]() eDrawings Viewer For MAC.

eDrawings Viewer For MAC.