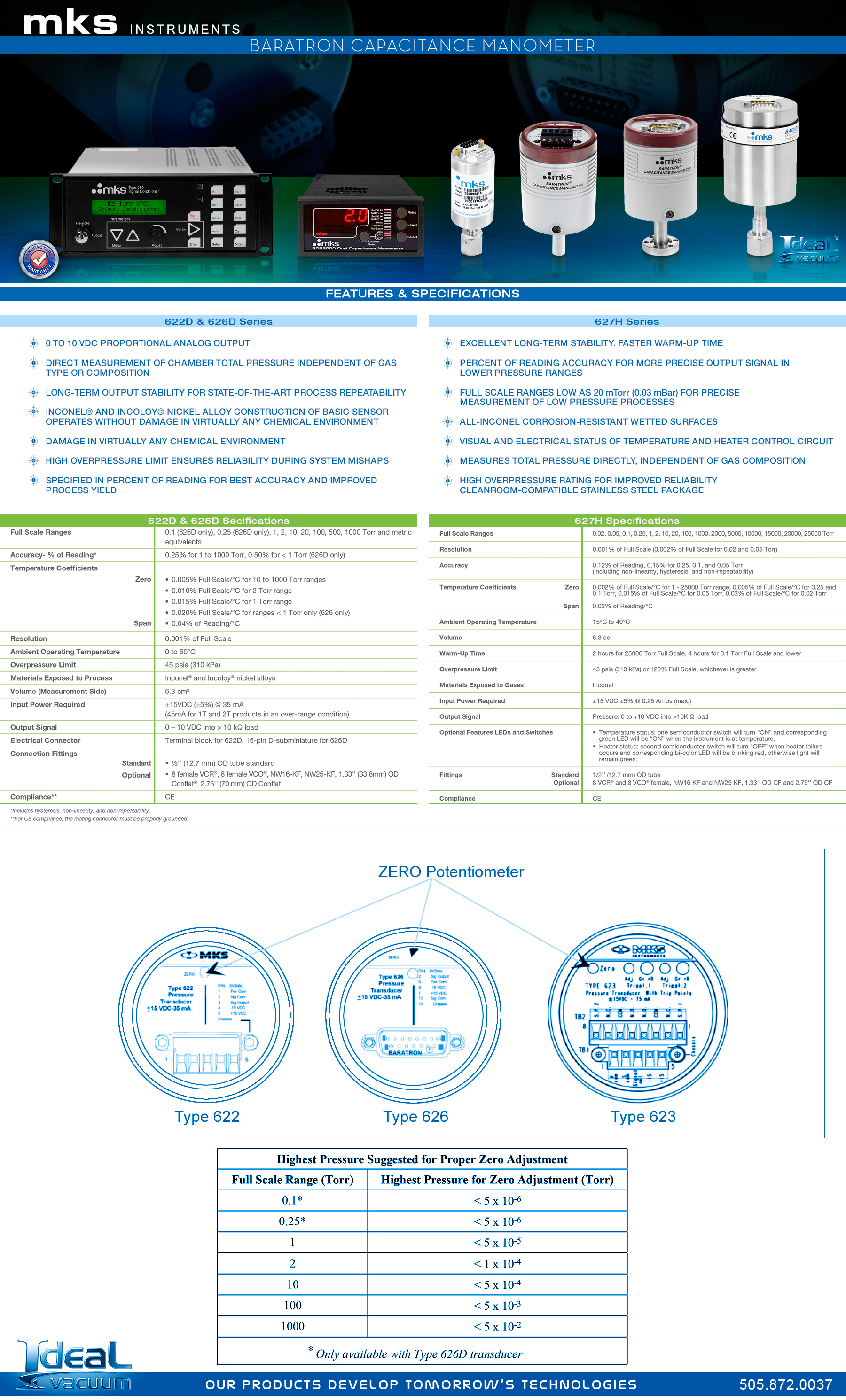

MKS 622D 10 Torr Baratron Absolute Capacitance Manometer, Vacuum Fitting 1/2 in Tube OD, Terminal Block Connector, MKS Part Number: 622D11TAE.

The MKS 622D unheated absolute Baratron® capacitance manometers are the latest analog, capacitance-based, high-performance vacuum and pressure transducers. They require ±15 VDC input voltage and provide a high-level 0-10 VDC analog output signal that is linear with pressure. This analog output can be interfaced with an MKS PDR2000 pressure controller, an MKS power supply/display instrument, or any instrument that meets these requirements. Changes in pressure/vacuum are determined by measuring the change in capacitance between the sensor’s diaphragm and an adjacent electrode disk. This capacitance change is converted to a useable output by patented signalconditioning electronic circuits. The radially-tensioned Inconel® diaphragm in the sensor provides very fast response (<20 msec in many cases), low hysteresis, excellent repeatability, very high resolution (to 0.001% of Full Scale), exceptionally high corrosion resistance, and double-walled welded construction for operator safety. The sensor itself can withstand repeated exposures to 45 psia (3.1 bar) without permanent degradation or shifting, allowing it to operate in virtually any process system. The MKS 622D Baratron capacitance manometers operate at ambient conditions. They are available in full scale pressure/vacuum ranges from 0.1 to 1000 Torr and are suited for many industrial, electronic, and research applications.

These listing is for an MKS Type 622D capacitance manometers having a terminal block connector, a 10 Torr full scale maximum vacuum pressure reading value, a 1/2 inch OD tube vacuum connection, and have MKS part number 622D11TAE.

Compatible Controller and Cables:

Product Features:

- 0 to 10 VDC proportional analog output with terminal block connector

- Direct measurement of chamber total pressure independent of gas type or composition

- Long-term output stability for state-of-the-art process repeatability

- Inconel® and Incoloy® nickel alloy construction of basic sensor operates without damage in virtually any chemical environment

- High overpressure limit ensures reliability during system mishaps

- Specified in percent of reading for best accuracy and improved process yield