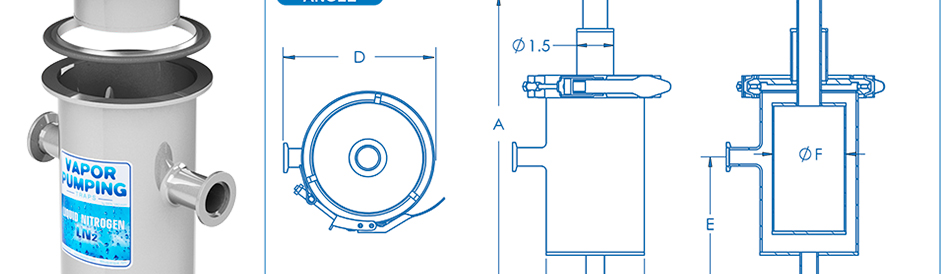

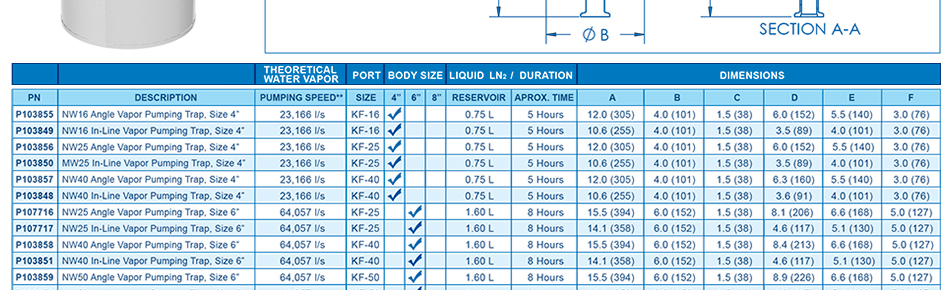

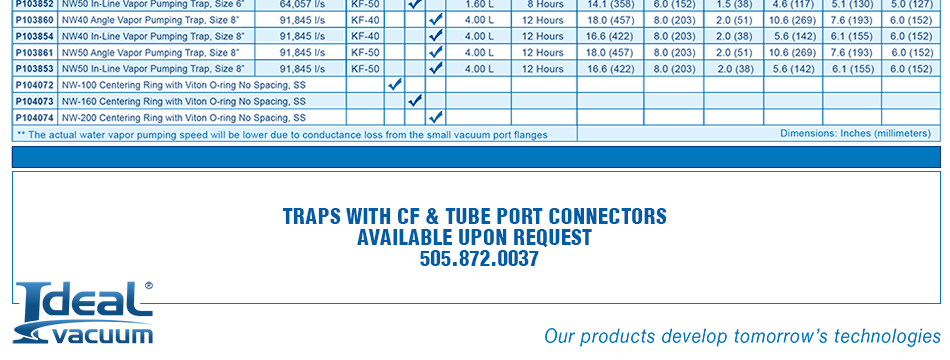

Ideal Vacuum Vapor-Pumping In-Line Liquid Nitrogen Trap Inlet KF50, with 0.75 in Ball Drain Valve

Body size: 6 in OD

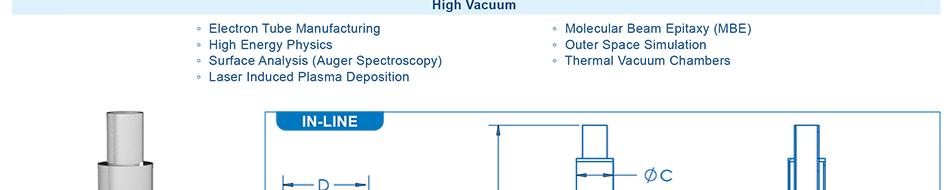

Ideal Vacuum Vapor-Pumping Liquid Nitrogen Traps (LNT) Series In-Line traps are capture type traps that collect condensable gas vapors such as water, solvents, etc. as they are being pumped from the vacuum chamber, but before they can intrude into the mechanical pump. These traps collect vapors by utilizing a refrigerant such as liquid nitrogen and should be the foremost choice in high moisture, condensable effluent applications. Without appropriate trapping, condensable vapors can intrude into the mechanical pump, limiting the ultimate base pressure of the pump to unacceptably high levels. These traps actually act as a pump producing lower base pressures and faster pump down. These In-Line traps extend the life of the pump; the hydrocarbon fluid, and minimize maintenance issues. The welded ball valve attachment allows for ease of cleaning and the potential recycling of liquid nitrogen.

Isolation valves can also be placed between any capture trap and the work chamber.

Isolation valves should always

be closed to prevent trapped gases from escaping into the work chamber when warming up the trap, during bake-outs,

maintenance cycles, etc.

The benefits of putting in service the correct In-Line traps are lower ultimate base pressures, cleaner chambers and extended periods of operation. Each trap offers simple reliable operation, along with high efficiency ratings of better than

99% and when correctly employed practically eliminate hydrocarbon back-streaming issues and are valuable additions to

any high vacuum system.

Features:

- Refill timetable for 6 inch OD body trap, 8 hours

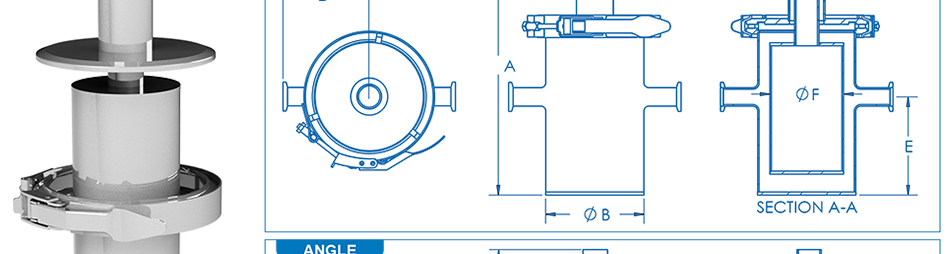

- Two piece clamped body design

- Removable liquid nitrogen reservoir

- Traps all condensable vapors

- Stainless Steel type 304 construction, Viton O-Ring

- Liquid Nitrogen Reservoir: 1.6 liter

- Welded 0.75 in ball valve