This Ideal Vacuum 3-Position Throttle Gate Valve is pneumatically operated with a ISO-F 200 (DN CF200) flange. It has a 3rd position that can be set to partially open. It is rated for high vacuum (HV) and comes with a standard Viton O-ring seal for the gate and Viton O-ring or OFHC copper gasket for the bonnet with a pneumatic controlled solenoid valve. This ISO-F flanged gate valve use Viton O-rings for the bellows and bonnet plate seals and are therefore limited to high-vacuum (HV) applications with ultimate pressures down to 1x10

-8 Torr.

The valves have a typical life of 300,000 cycles before needing service. They are made with corrosion resistant 304 stainless-steel gates and valve bodies. This 3-position control provides flexibility and precision in maintaining optimal conditions for various vacuum deposition processes, particularly in thin films deposition process chamber systems.

Application in Physical Vapor Deposition Coating Chambers

This 3-position gate valve is designed for dependable high vacuum applications and are often used in combination with cryo, turbo, and ion high vacuum pumps. It has found increased usage in throttled vacuum processes like PVD magnetron sputtering deposition.

In a PVD coating chamber, such as in sputtering systems, a 3-position gate valve is often used to control the connection between the turbo-molecular pump and the main process chamber. These gate valves allow for precise control of the vacuum system and can isolate the pump, protect the chamber, and adjust the pumping speed. The three positions of a typical 3-position gate valve are:

1. Fully Open Position:

Maximum conductance, full turbo pumping speed, used for initial evacuation or when maintaining high vacuum during deposition.

2. Partially Open (Throttling Position):

Purpose: In the partially open position, the gate valve is only partially open, throttling the conductance between the chamber and the turbo pump.Throttling is important when working with reactive gases (e.g., oxygen or nitrogen in reactive sputtering) or when you need to fine-tune the pressure for optimal film growth.

This partially open position is manually set and adjusted one time during installation and can be changed anytime to run a different process condition.

3. Fully Closed Position:

Purpose: In the fully closed position, the gate valve completely isolates the turbo pump from the main chamber.

Use Case: This position is used to protect the turbo pump during processes like chamber venting, load-lock chamber sample loading, or when the chamber is being exposed to atmospheric pressure. It prevents contaminants or atmospheric air from entering the turbo pump, which could damage it.

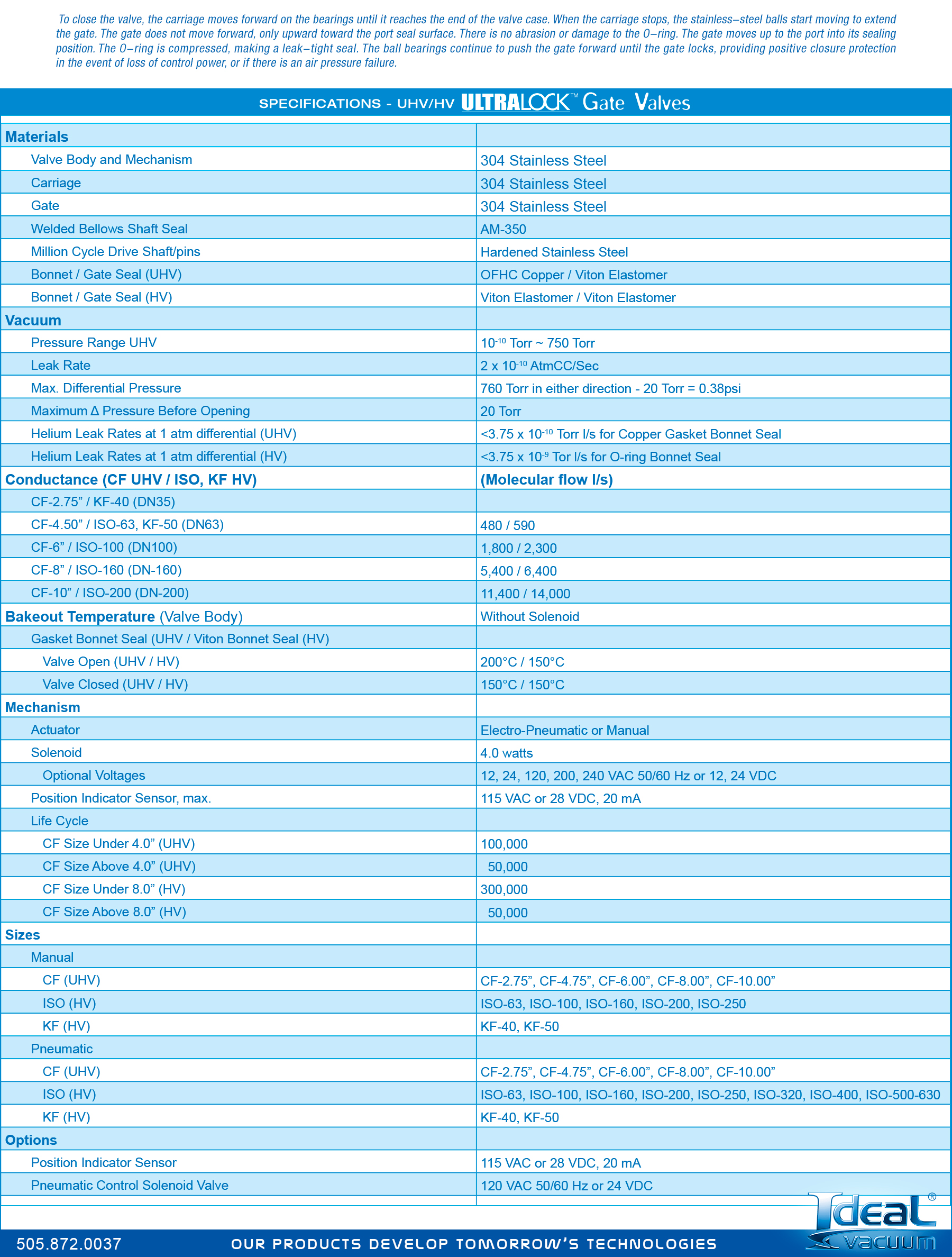

Specifications:

Specifications and features:

- Material

- Body

- Carriage

- Linkage type - SUS304

- Ball type Size under 10” - SUS304

- Ball type Size above 10”(included) - SUS304, A6061-T6

- Gate

- Linkage type - SUS304

- Ball type Size under 10” - SUS304

- Ball type Size above 10”(included) - A6061-T6

- Bellows

- Life Cycle

- HV :DN200 - 300,000 cycles

- UHV :DN200 - 50,000 cycles

- Helium leak rates at 1 atm differential

- <2×10-9 mbar·l /sec for O-ring

- <5×10-10 mbar·l /sec for gasket seal

- Bake Temperature

- Open - 200 °C Viton bonnet seal

- Closed - 150 °C Viton bonnet seal

- Pressure Range (mbar)

- HV: 1x10-8 ~ 1000

- UHV: 1x10-10 ~1000

- Maximum delta P (mbar)

- Standard Seal

- Gate - Viton O-ring

- Bonnet - Viton O-ring or OFHC copper gasket

- Actuator - Pneumatic

- Compressed air supply

- Tube connection - 6mm

- Pressure range - 4-6 Kg/cm2(overpressure)

- Surface Treatment - Scotch Polished

- Options

- Position indicator

- Pneumatic control solenoid valve

- Roughing port

- Other material Gate O-ring seal

Please see the downloads for more information on this gate valve and other related valve configurations.

![]() eDrawings Viewer For Windows

eDrawings Viewer For Windows![]() eDrawings Viewer For MAC.

eDrawings Viewer For MAC.