Edwards STP-451 3 Axis Magnetic Bearing Ultra High Turbomolecular Pump, 480 l/s Pumping Speed, DN160CF CF 8 in.

Pump Only NO Accessories. Edwards Part Number B74841010

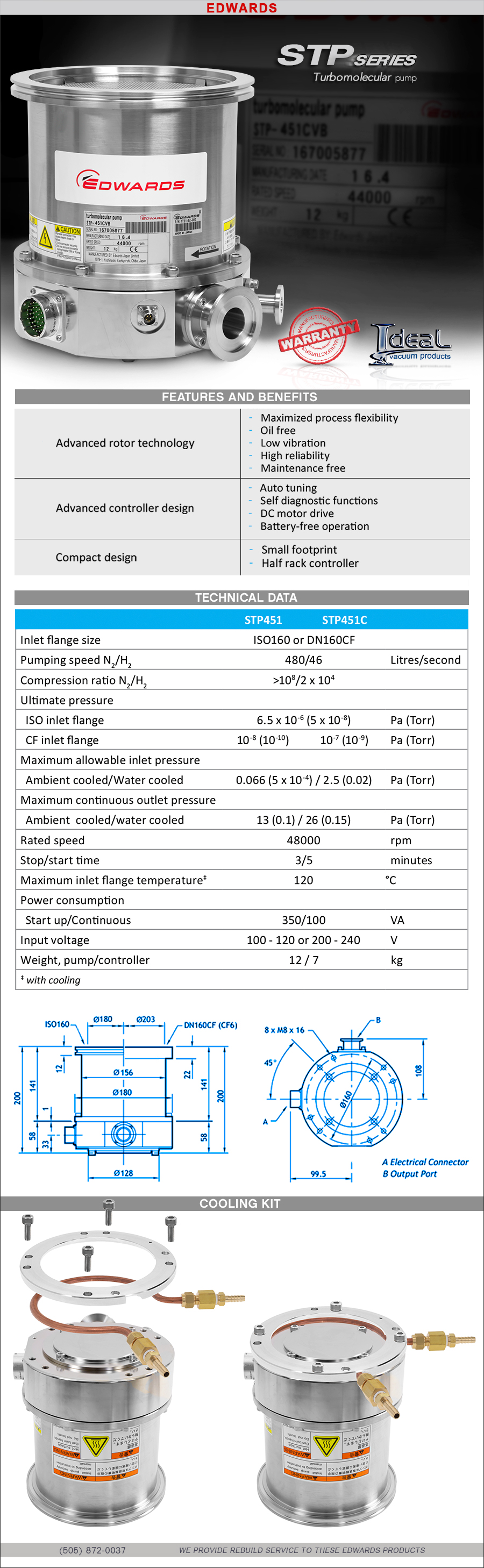

This listing is for the new Edwards STP-451 3 Axis Magnetic Bearing Ultra High Turbomolecular Pump. To be used with the Edwards SCU-350 Control Unit, pumping speed of 480 liters per second (l/s) of nitrogen, DN160CF CF 8 in. inlet flange, ISO KF-25 exhaust foreline flange, and KF-10 purge port with the corrosion model. A basic pump system would require a Edwards STP-451 pump, a SCU-350 controller, a water cooling accessory and a suitable backing roughing pump. The Edwards STP-451 turbomolecular pump offers field proven reliability for use in electron miscroscopes, scientific instruments and semiconductor applications.

The STP-451 is a series of magnetically-levitated turbomolecular pumps. The STP pump is configured so that rotor blade and the stator blade are aligned

alternately in the axial direction. Gas molecules are pumped from the inlet port to the

outlet port by the high speed rotation of the rotor.

The Rotor blade is supported by the magnetic bearing without mechanical contact.

Therefore the STP pump requires no lubrication oil unlike conventional turbomolecular

pumps using ball bearings.

The magnetic bearing consists of 3 pairs of active magnetic bearings. The rotor is

supported in the radial direction by 2 pairs of radial direction active magnetic bearings

that consist of radial sensor and radial electromagnet. A pair of axial direction

active magnetic bearings consists of axial sensor and axial electromagnet to

support the rotor in the axial direction. Because the rotor is thus supported without

mechanical contact, it can rotate with very low vibration.

There is less heat generated from magnetic bearings because there is no friction.

Therefore the STP pump requires no cooling. However, the STP pump requires water

cooling or air cooling during baking, gas pumping or any process.

Taking into consideration a breakage of magnetic bearings, touch down bearings and

coated with solid lubrication have been installed. They do not contact the rotor

during the rated operation. A radial sensor, an axial sensor, a rotational speed sensor and a temperature sensor

always monitor the magnetic bearing as well as the rotor. If an abnormality/error

occurs, the rotor will stop.

To ensure a high level of resistance to corrosion, the corrosion resistant models STP (C) have nickel coated rotors/stators and pump internals suitable for ion implantation and plasma etching. These corrosion resistant pumps have a KF10 nitrogen purge facility, a constant flow of nitrogen through the pump dilutes corrosive gases minimizing their damage to the pumps motor and sensor coils. All accessories for this pump are available on this website or call 505-872-0037 for details. For complete specs, see graphic below or download the STP manual.pdf in AVAILABLE DOWNLOADS below.