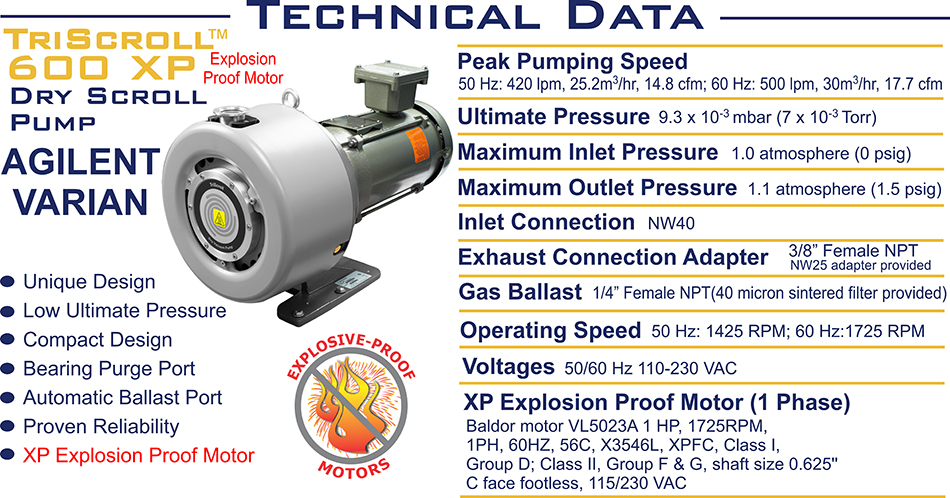

Agilent Varian TriScroll 600 Oil-Free Dry Scroll With XP Explosion Proof Motor 110/220VAC 1 Phase

This Agilent Varian 600 Triscroll dry scroll vacuum pump comes with a XP Explosion Proof Motor. It is designed for high reliability with a 17.7 CFM pumping speed and an ultimate pressure of 7x10-3 Torr. The Agilent Varian Triscroll pumps produce oil-free vacuum at high speed and low ultimate pressure. The unique patented TriScroll features proven reliability and durability leading to superior cost of ownership and consistent performance. Applications include: Scanning

Electron Microscopes, Primary backing pump for turbo systems, General purpose laboratory applications, Beam Lines, Drying Ovens, Load Locks and Transfer Chambers, Cryogenics, Manufacturing/Glove Box Enclosers, Leak Detection. These Agilent Varian 600 Triscroll vacuum pumps have product number PTS06001UNIV. This pump has a Baldor Explosion Proof Motor VL5023A 1 HP, 1725RPM, 1PH, 60HZ, 56C, X3546L, XPFC and is 110/230 VAC compatible.

Explosion Proof Motor Specifications (XP Class, Group, & Division)

- Class I, Group D

- Class II, Group F & G

- Division I

Typical Customer Applications That Are In Class I Environments

(Flammable Gases & Vapors) Include:

- Spray painting and finishing areas

- Utility gas plants

- Petroleum refining plants

- Petroleum dispensing locations

- Dry cleaning facilities

- Dip tanks containing combustible or flammable fluids

- Plant facilities extracting solvents

- Inhalation anesthetic areas

- Process facilities manufacturing or using nitro-cellulose (class II as well).

- Aircraft hangars and fuel servicing areas.

- Gas stations.

Typical Customer Applications That Are In Class II Environments

(Combustible Dust) Include:

- Flour mills.

- Feed mills.

- Grain elevators and grain handling facilities.

- Fire work plants and storage areas.

- Aluminum manufacturing and storage areas.

- Magnesium manufacturing and storage areas.

- Coal preparation and handling facilities.

- Starch manufacturing and storage areas.

- Confectionary plants.

- Pulverized sugar and cocoa manufacturing plants. Packaging and

storage plants.

- Spice grinding and storage plants.

These explosion proof XP Scroll Pumps have an electrically sealed explosion proof motor. These explosion-proof motors are designed to limit the chance that a spark from inside the motor could travel outward to ignite air born flammable vapors or materials in the laboratory where the pump is operating. Explosion proof vacuum pumps are typically needed in applications where flammable materials may accidentally leak into the room air where these pumps are used. Explosion Proof vacuum pumps are

NOT designed to evacuate vapors and gas mixtures which are explosive if ignited.