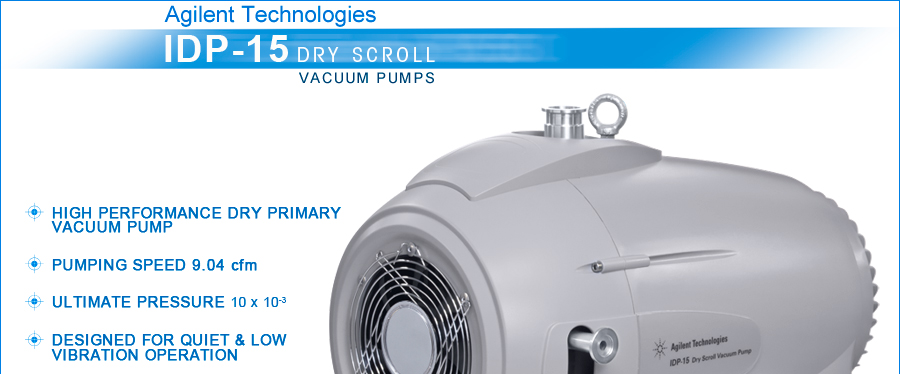

Agilent IDP-15 Hermetically-Sealed Dry Scroll Vacuum Pump, 115 - 230VAC. PN: X3815-64000

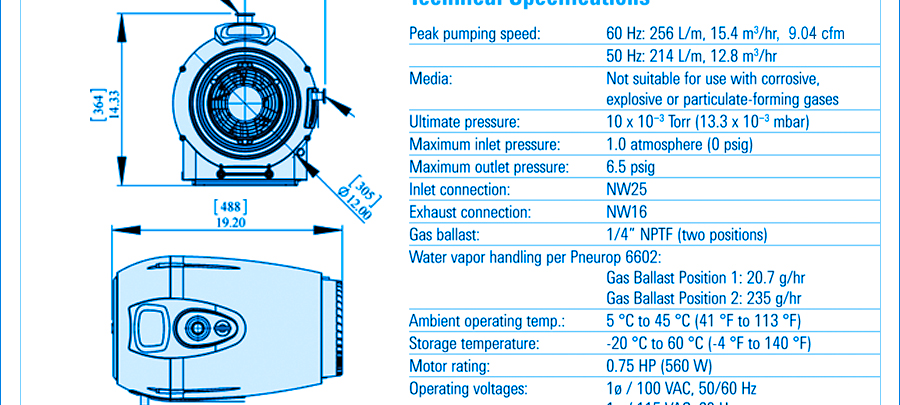

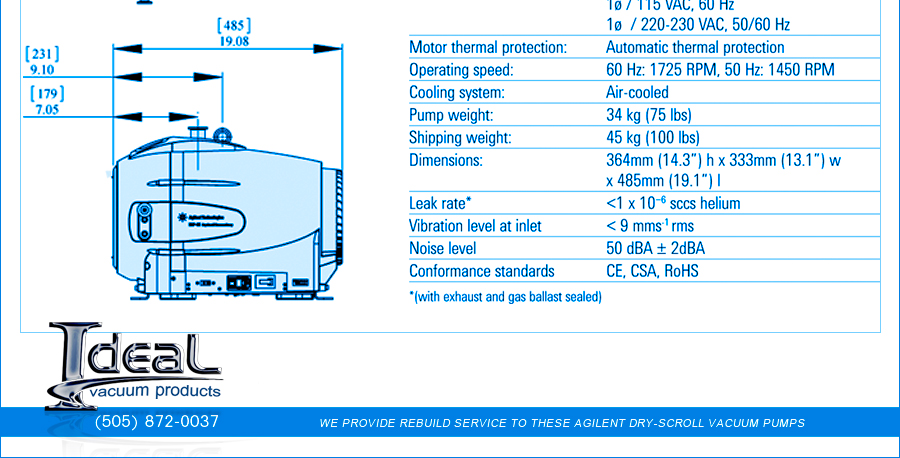

The Agilent Varian IDP-15 dry scroll vacuum pump is designed for extremely quiet < 50 dBA and low vibration operation, delivering a peak pumping speed of 9.4 cfm (15.4 m3/h) at 60 Hz, and produces an ultimate pressure of 10 mTorr. These new Agilent IDP-15 dry scroll pumps are hermetically-sealed being appropriate for rare gas and helium 3He recirculation applications. The hermetic design with the vacuum space completely isolated from the motor and bearings provides a clean gas path through the pump, which eliminates any risk of oil or grease contamination. These key design elements of the IDP-15 allow the motor and bearings to run at atmospheric pressure which isolates them from being exposed to any vacuum process gases or water vapor from the application. The Agilent IDP-15 supports a global single-phase motor for operating voltages ranges between 100-120V or 200-230 VAC at 50/60Hz and incorporates a easy accessible simple switch to change between high and low voltage use. This IDP-15 model, Agilent technologies part number X3815-64000, does not include an Integrated Inlet Isolation Valve.

High vacuum pumps, such as turbo molecular pumps, are increasingly used in conjunction with dry backing pump technology. Pumps based on scroll technology have become the dry pump technology of choice for backing turbo molecular high vacuum pumps. There are several factors that make these Agilent Varian IDP-15 scroll technology the superior dry pump choice, including clean, predictable performance, lower vibration and noise, and long service life.

Modern Agilent IDP-15 scroll technology is based on smooth orbital operation, the vacuum pump cycle of gas compression and discharge occurs with minimal pulsation and very low vibration. Depending on the application, vibration can have some adverse effects, and may lead to the use of additional components such as vibration isolators. The new Agilent IDP-15 is the dry pump of choice in a wide variety of applications where vibration is a factor.

Current scroll technology and tip seal design are factors that work together to provide low base pressure, and a gradual increase in base pressure over the service life. This gradual increase in base pressure allows maintenance to be done before the vacuum becomes unacceptable and cuts unscheduled downtime. A typical scroll pump like the Agilent IDP-15 will achieve a base pressure of 10 mTorr.

These Agilent IDP-15 dry scroll pumps create vacuum using a simple dual scroll mechanism in which one of the nested scrolls orbits about the other, creating moving zones of captured gas. Gas enters the scroll set at the outside perimeter and is displaced and compressed toward the center of the hub where it is exhausted. The uncomplicated dual scroll design offers many benefits including lower noise and vibration levels, simple and infrequent maintenance requirements, plus the elimination of catastrophic failure modes.

These new Agilent Technologies IDP-15 includes improved solid tip seals for longer tip seal life and longer service interval. The solid tip seal material performs well for condensable vapor applications. The tip seal replacement for the IDP-15 is easier than ever before. All that is needed is simple tools, flat head screw driver, 4 and 5 mm Allen wrenches, isopropyl alcohol, lint-free wipes, and tip seal kit part number X3815-67000. Please see pages 24 - 30 of the instruction manual for tip seal replacement procedure. An instruction manual and brochures in PDF format for the new Agilent IDP-15 hermetically-sealed dry scroll vacuum pumps can be downloaded in our available download section below.

![]() eDrawings Viewer For Windows

eDrawings Viewer For Windows![]() eDrawings Viewer For MAC.

eDrawings Viewer For MAC.