HALO View Replacement/Upgrade Window for Non-illuminated Viewport, ISO-250, LF250, 3/8 in. Fused Quartz.

This fused quartz window is a replacement or upgrade for the Ideal Vacuum ISO-250 HALO non-illuminated Viewport Window assembly. Non-illuminated HALO view windows are field serviceable. Please see the HALO View Window Manual, available in the downloads, for instructions on replacing the window media.

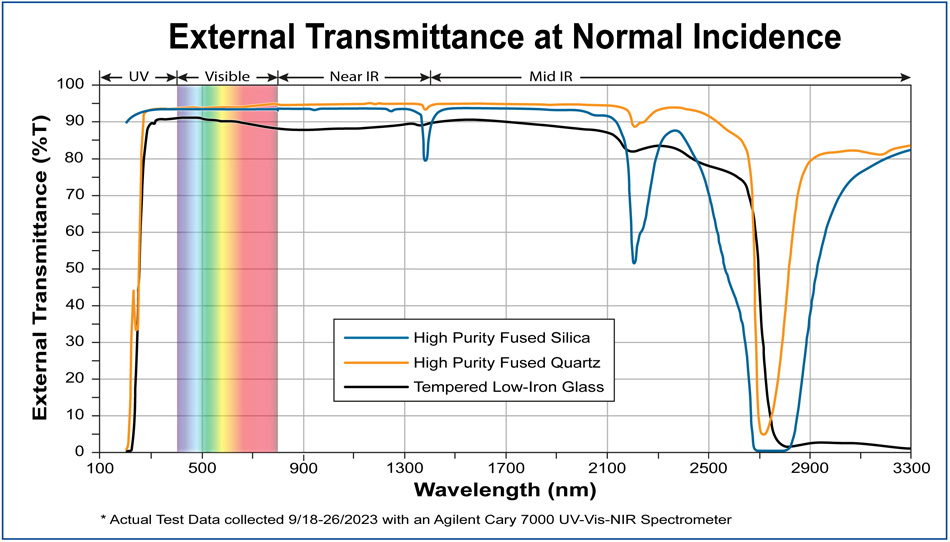

Our fused quartz windows are manufactured with the highest quality natural quartz resulting in the highest levels of purity and lowest inclusion and bubble levels. Comparable to Heraeus TSC-3, these windows have improved transmittance, and a wider useful wavelength range than standard glass. Characteristics include low refractive index variations and low thermal expansion coefficient. Fused quartz is used for semiconductor applications such as plasma etch and deposition systems and recommended when low alkali and low aluminum content are specified. It is often used for transmissive optics in the visible and near-to-mid infrared wavelengths where a high laser damage threshold is required. Fused quartz has absorbtion bands in the 2600 to 2900 nm region, similar to fused silica but not as strong. It is unsuitable for UV work due to absorbtion in the 270 nm region.

We also offer HALO View Window assemblies and replacement panes with standard low-iron tempered glass or fused silica. Tempered glass is commonly used for general, direct observation of roughing or high-vacuum chamber processes and can be used to facilitate optical alignments of chamber components, observe degassing of fluids, or used to help teach in-vacuo processes by direct observation. The glass material is standard low-iron float glass. Surface quality and flatness is Q4 per ASTM 1036-06 and 1048-04. The low iron content of the glass results in it having a slight blueish tint. This economical glass is unsuitable for laser experiments below visible or beyond near-infrared (NIR) wavelengths.

Our high purity fused silica windows are ground and polished to optical grade on both sides with a total thickness variation (TTV) of <10µm, a surface finish of S/D 40/20, and a surface roughness of Ra < 1 nm (comparable to Corning HPFS 7980). These windows have appreciably improved transmittance, and a wider useful wavelength range than standard glass. Characteristics include extraordinarily low refractive index variations, low birefringence values, and an ultra-low thermal expansion coefficient. Fused silica is used for transmissive optics where a high laser damage threshold is required. Fused silica is used for optics operating in the deep UV, visible, and the near infrared wavelength range.

Note that fused quartz stock is limited as Ideal Vacuum is transitioning to fused silica as its premium window offering. Also note that fused quartz windows may be erroneously labeled with fused silica part numbers. You may verify your window material by checking your sales invoice.

Non-illuminated HALO Viewports are field serviceable. Window panes can be replaced or changed to another material if experiment requirements change. Please see the graph below for the transmissivity curves of tempered glass, fused quartz, and fused silica:

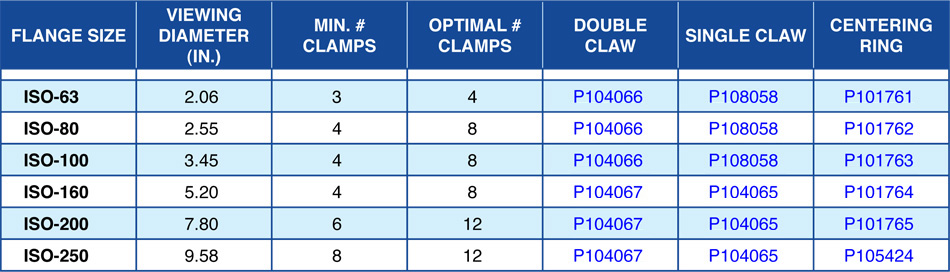

Non-illuminated HALO viewing windows are available in ISO 63, 80, 100, 160, 200 and 250 sizes and are used in place of blank ISO flanges. Like other ISO fittings, these ISO flanged windows use either single or double claw clamps along with a centering ring fitted with an O-ring. Use double claw clamps on ISO-K to ISO-K connections. Use single claw clamps on ISO-K to ISO-F (bolted) connections. The recommended number and type of claw clamps and the centering ring required is shown in the table below:

Our ISO viewing windows employ an innovative, zero metal-to-glass contact design that holds the 3/8” thick window pane to a stainless steel mounting flange. This cushioned window mounting system ensures operator safety and is less prone to leakage than other viewport window configurations, even at high-vacuum pressures. Ideal Vacuum ISO HALO viewing windows are delivered fully assembled and use Viton O-rings and Teflon spacers. Bakeout temperatures to 150 °C are permissible.

NOTE: All viewing windows or viewports are inherently fragile, should be handled carefully, and always inspected before use. Ideal Vacuum viewing windows are designed and rated for VACUUM ONLY and can be susceptible to thermal shock if exposed to rapid temperature changes (>10° C /min). If directing a laser beam through the window, make sure the laser’s wavelength can be reasonably transmitted through the window’s material. Please download and read all the safety warnings in the HALO View Window User Manual.

|